This article explores why carbon fiber has become the gold standard for high-performance drone frames. We will dive into what makes this advanced material uniquely suited for flight, examining its incredible strength-to-weight ratio, its role in providing stability and durability, and how it dramatically enhances a drone’s agility and flight time. By comparing it to other materials like aluminum and plastic, and looking at how frames are made, we’ll provide a complete picture of carbon fiber’s dominance in the drone industry, offering insights for both new pilots and experienced engineers. The key takeaway is that carbon fiber’s unique combination of properties directly solves the biggest challenges in drone design, making it the undisputed champion material.

Table of Contents

Part 1: Introduction – The Quest for the Ultimate Drone Frame

We’re living in an age of flight unlike any other. Drones, or Unmanned Aerial Vehicles (UAVs), have exploded from the realm of hobbyist gadgets into indispensable tools across countless industries. They paint our movie screens with breathtaking aerial shots, help farmers monitor crops with pinpoint precision, and are on the verge of revolutionizing package delivery. They are the eyes in the sky for search and rescue teams and the agile athletes of a thrilling new sport: FPV drone racing.

But what holds all this incredible technology together? What is the backbone that allows a drone to be both a graceful cinematic platform and a rugged, high-speed racer? It all comes down to the frame.

The frame is far more than just a skeleton. It’s the foundation that dictates a drone’s very character. It determines how long it can fly, how much it can carry, how nimbly it can move, and how well it can survive an unexpected “creative landing.” The ultimate engineering puzzle has always been to find a material that is incredibly strong, ridiculously light, and unyieldingly stiff. For years, designers balanced the trade-offs between metals, plastics, and wood. And then, one material changed the game completely.

Carbon fiber. This advanced composite material has become the undisputed champion in the world of high-performance drones. It has met every engineering challenge and set a new gold standard. So, what makes this sleek, black material so special? Let’s dive deep into the science, the real-world advantages, and the practical reasons why carbon fiber is the best choice for building the future of flight.

Part 2: What Exactly is Carbon Fiber? Unraveling the Material Science

When we talk about a “carbon fiber” drone frame, the term is a bit of a shorthand. What we’re actually talking about is a high-tech composite material known as Carbon Fiber Reinforced Polymer (CFRP). It’s a team effort between two key components, and understanding them is the first step to appreciating why it’s so perfect for drones.

The Fibers: The Source of Super Strength

Imagine threads thinner than a single human hair, yet stronger than steel. That’s the essence of the carbon filaments at the heart of the material. These fibers are created through a complex, high-temperature process called carbonization. It starts with a precursor material, usually a polymer called polyacrylonitrile (PAN), which is spun into fibers.

These fibers are then heated to extreme temperatures in a furnace without any oxygen. This intense heat burns away almost all the non-carbon atoms, leaving behind long, interlocking chains of carbon atoms. These atoms form crystals that are aligned along the length of the fiber, creating a molecular structure with incredible tensile strength. It’s this unique atomic bond that gives carbon fiber its legendary ability to resist being pulled apart.

The Matrix: The Glue That Binds It All

A bundle of even the strongest threads isn’t very useful for building a rigid structure. That’s where the second part of the team comes in: the matrix. This is typically a hardened polymer, like an epoxy resin. The carbon fibers are impregnated with this resin, which then cures and hardens around them.

Think of it like reinforced concrete. The steel rebar provides the tensile strength, but the concrete holds it all together, gives it shape, and distributes the forces. In CFRP, the carbon fibers are the rebar, and the epoxy resin is the concrete. The resin’s job is crucial:

- It binds the millions of tiny fibers together into a solid, rigid part.

- It protects the fibers from scratches and environmental damage.

- It transfers the stress and load evenly across all the fibers.

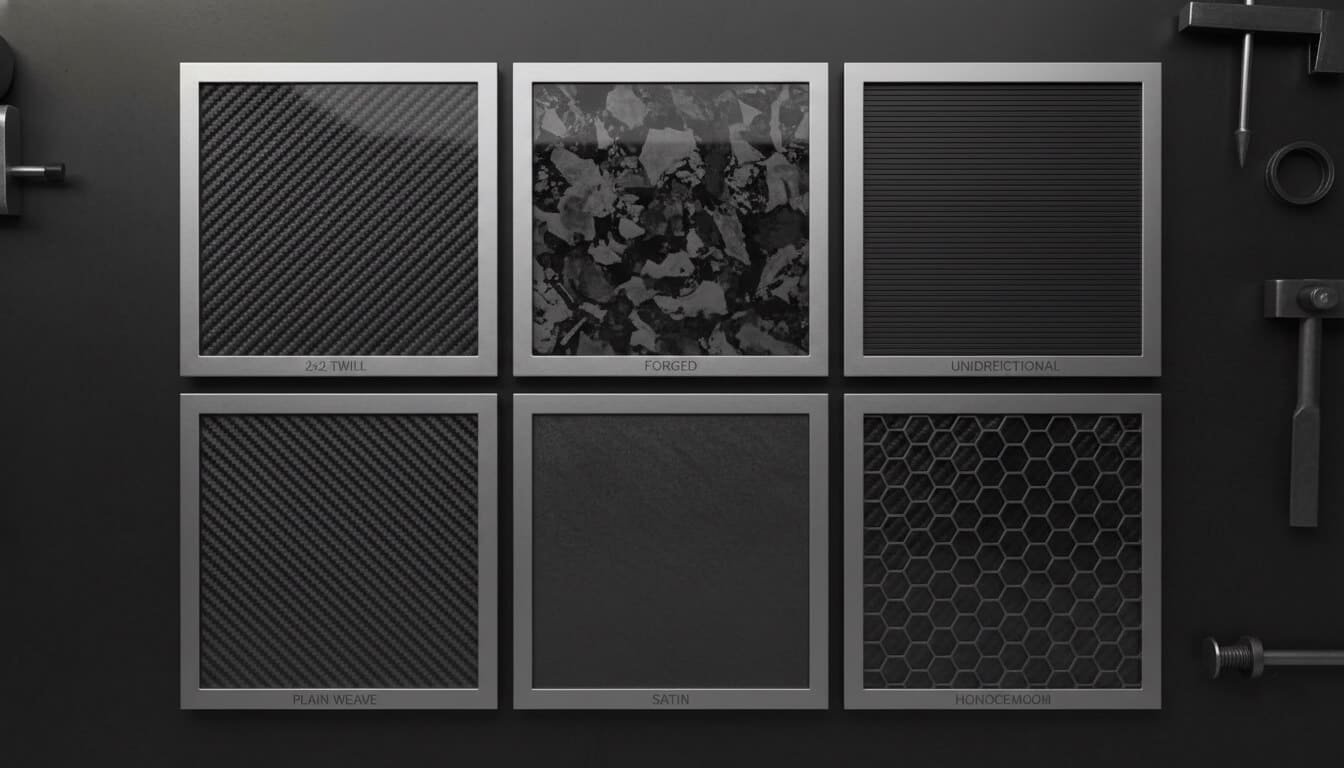

Weaving the Fabric: Not All Carbon Fiber is the Same

Before being infused with resin, the carbon fibers are woven into fabrics, and the pattern of this weave has a huge impact on the final material’s properties. For drone frames, you’ll most commonly encounter these types:

- Twill Weave: This is the champion of drone frames. It has a distinct diagonal pattern. Twill weave is strong, relatively pliable (making it great for manufacturing), and has that classic, high-end carbon fiber look. It offers a fantastic balance of strength in multiple directions.

- Plain Weave: A simple, symmetrical over-under checkerboard pattern. It’s very stable but not as flexible as twill, making it slightly less common for complex drone parts.

- Unidirectional: As the name suggests, all the fibers in this fabric run in a single, parallel direction. This creates a material with mind-blowing strength along that one axis, but it’s weak in other directions. Drone designers use unidirectional layers strategically inside a frame’s arms to provide maximum stiffness against the bending forces from the motors, without adding excess weight.

This ability to mix and match weaves and layer them in specific orientations is what makes carbon fiber an intelligent material. Unlike a metal like aluminum, which is equally strong in all directions (isotropic), carbon fiber is anisotropic. Engineers can build a frame that is massively strong and stiff exactly where it needs to be, revolutionizing drone design and performance.

Part 3: The Core Advantages: Why Carbon Fiber Dominates Drone Design

Understanding the science behind carbon fiber is one thing, but seeing how its unique properties translate into real-world flight performance is where things get truly exciting. Each advantage directly addresses a fundamental challenge in drone engineering, pushing the boundaries of what’s possible.

The Holy Grail: The Phenomenal Strength-to-Weight Ratio

This is, without a doubt, the number one reason carbon fiber is king. In the world of aviation, weight is everything. Every single gram requires energy to lift and move. Carbon fiber shatters the traditional compromise between strength and weight.

Let’s put it in perspective. Pound for pound, carbon fiber is about five times stronger than steel, yet it can be as light as plastic. This incredible efficiency means designers can build frames that are tough enough to survive hard crashes without weighing the drone down.

| Property | Carbon Fiber (Typical) | Aluminum (6061-T6) | Titanium (Ti-6Al-4V) | Steel (4130) |

|---|---|---|---|---|

| Density (g/cm³) | ~1.6 | 2.7 | 4.5 | 7.85 |

| Tensile Strength (MPa) | Up to 3000 | ~310 | ~900 | ~670 |

| Specific Strength (Strength/Density) | Highest | Low | High | Lowest |

This superior strength-to-weight ratio has a direct impact on three critical areas of drone performance:

- Longer Flight Times: It’s simple physics. A lighter airframe requires less thrust from the motors to stay airborne. This lower energy consumption directly translates to more time in the air on a single battery charge. Shaving even 50 grams off a frame can mean an extra minute or two of precious flight time.

- Higher Payload Capacity: Because the frame itself is so light, the drone’s motors can dedicate more of their lifting power to a payload. This is a game-changer for professional cinematographers who need to carry heavy cinema cameras, or for industrial applications using complex sensors and scanners.

- Incredible Agility and Speed: Lighter objects have less inertia. This means a drone with a carbon fiber frame can accelerate, stop, and change direction with blistering speed. This is the secret behind the mind-bending acrobatics of freestyle drones and the razor-sharp cornering of FPV racing quads.

Extreme Rigidity and Stiffness: The Foundation of Stable Flight

Strength is important, but stiffness—a material’s resistance to bending—is arguably even more critical for a stable drone. A flimsy frame that flexes under load is a pilot’s worst nightmare. It leads to sloppy controls and, more importantly, vibrations.

Motors and propellers generate high-frequency vibrations that can wreak havoc on a drone. These vibrations travel through the frame and can:

- Ruin Video Footage: Vibrations cause the infamous “jello” effect in videos, a wobbly distortion that makes footage unusable.

- Confuse the Flight Controller: A drone’s brain, the flight controller, relies on sensitive gyroscopes and accelerometers to stay level. Excessive vibrations can interfere with these sensors, leading to unstable flight or unpredictable behavior.

Carbon fiber’s composite structure is exceptionally stiff and brilliant at damping these vibrations. It absorbs the buzz from the motors rather than transmitting it. This inherent rigidity ensures that every input from the pilot is translated directly into precise movement, creating a “locked-in” feel that is essential for capturing smooth cinematic shots or navigating a racecourse with confidence.

Unmatched Durability and Fatigue Resistance

Let’s be honest: drones crash. Whether you’re a beginner learning to fly or a professional pushing the limits, impacts are a part of the experience. Carbon fiber frames are designed to be resilient.

Unlike aluminum, which will bend and stay permanently deformed after a hard impact, carbon fiber has a degree of flex. It can absorb a significant amount of impact energy and spring back to its original shape. If the impact is too severe, it will break, but this is often a clean break of a single part (like an arm), which can be easily replaced. A bent aluminum frame, on the other hand, often means the entire structure is compromised.

Furthermore, carbon fiber has excellent fatigue resistance. The constant stresses of flight—takeoffs, landings, sharp turns—can weaken metals over time, leading to cracks. Carbon fiber can withstand these repeated stress cycles for thousands of flights without losing its structural integrity, ensuring a long and reliable operational life.

Environmental and Chemical Resistance

Drones are often flown in challenging environments. Rain, humidity, and salty coastal air can be a death sentence for metal frames, leading to rust and corrosion. Carbon fiber is completely immune to this. It’s a non-metallic composite that simply doesn’t corrode, making it the perfect choice for all-weather operations or marine applications.

It also has a very low coefficient of thermal expansion. This means it won’t warp, expand, or contract in extreme heat or cold, ensuring that all the sensitive electronic components mounted to the frame remain perfectly aligned and secure, no matter the conditions.

Part 4: Material Showdown: Carbon Fiber vs. The Alternatives

To truly appreciate why carbon fiber is the best, it helps to see how it stacks up against the other common materials used in drone construction. Each material has its place, but for high-performance applications, the choice becomes clear.

Carbon Fiber vs. Aluminum Alloys: The Classic Rivalry

Aluminum, especially alloys like 6061 and 7075, is a respectable material. It’s strong, relatively light, and has been a staple in aviation for decades. However, when it comes to drones, it faces some serious challenges against carbon fiber.

- Performance: Carbon fiber wins, hands down. Its strength-to-weight ratio is far superior, meaning for the same level of strength, an aluminum frame will always be heavier. This impacts everything from flight time to agility.

- Durability: This is a point of debate. Aluminum bends on impact, which permanently damages the frame’s geometry. Carbon fiber flexes back or breaks cleanly. From a repair standpoint, it’s often easier and cheaper to replace a single broken carbon fiber arm than an entire bent aluminum frame.

- Vibration: Aluminum is a poor vibration damper. It acts like a tuning fork, transmitting motor vibrations throughout the entire airframe, which is bad for cameras and flight controllers.

- Cost: This is aluminum’s one major advantage. It is significantly cheaper and much easier to machine, making it a viable option for some large-scale industrial drones or budget-conscious builds.

Verdict: Aluminum is a dependable workhorse, but carbon fiber is the high-performance racehorse.

Carbon Fiber vs. Engineering Plastics: The Budget Options

Plastics like ABS, Nylon, and composite materials like G-10 or fiberglass are very common in the drone world, especially at the entry-level.

- Performance: Plastics are lightweight but lack the stiffness and strength of carbon fiber. This flexibility, while making them resilient to minor bumps, results in poor flight performance, excessive vibration, and a wobbly, unresponsive feel in the air.

- Durability: They are great for beginners because they can absorb a lot of impact without breaking. A plastic frame for a toy drone can bounce off walls and keep flying. However, this same flexibility makes them unsuitable for carrying any significant payload or for precise flight.

- Cost: Plastics are, by far, the cheapest material to produce, especially through injection molding. This makes them perfect for toy-grade drones, propeller guards, and 3D-printed accessory parts.

Verdict: Excellent for toys, beginner drones, and accessories, but they simply can’t provide the rigid platform needed for serious aerial work or racing.

Carbon Fiber vs. Titanium: The Premium Contender

Titanium is an exotic material known for its incredible strength and toughness. It’s a step above aluminum and is used in high-end aerospace applications.

- Performance: Titanium has an excellent strength-to-weight ratio, but it still doesn’t beat carbon fiber. It is also much denser, so a titanium frame would be heavier than a carbon fiber one of equivalent strength.

- Durability: Titanium is exceptionally tough and resistant to damage, even more so than carbon fiber in some scenarios.

- Cost: Titanium’s downfall is its astronomical price and the extreme difficulty in machining it. The cost to produce a titanium drone frame would be many times higher than a carbon fiber one, placing it out of reach for all but the most specialized military or deep-sea drone applications.

Verdict: An incredible material, but its cost and weight make carbon fiber the more practical and higher-performing choice for almost every drone application.

| Material | Strength-to-Weight | Stiffness | Vibration Damping | Cost | Best For |

|---|---|---|---|---|---|

| Carbon Fiber | Excellent (5/5) | Excellent (5/5) | Excellent (5/5) | High (2/5) | High-Performance, Racing, Cinematography |

| Aluminum | Good (3/5) | Good (3/5) | Poor (1/5) | Medium (3/5) | Industrial UAVs, Budget Builds |

| Plastics (Nylon/ABS) | Poor (1/5) | Poor (1/5) | Fair (2/5) | Low (5/5) | Toy Drones, Beginner Quads, Accessories |

| Titanium | Very Good (4/5) | Very Good (4/5) | Poor (1/5) | Very High (1/5) | Extreme Environment / Military Drones |

Part 5: From Design to Reality: How a Carbon Fiber Drone Frame is Made

Creating a high-quality carbon fiber drone frame is a blend of digital precision and advanced manufacturing. It’s a fascinating process that turns a raw material into a perfectly engineered piece of flight equipment.

The Digital Blueprint: CAD and Stress Analysis

Everything begins on a computer. Drone designers use Computer-Aided Design (CAD) software to create a 3D model of the frame. This isn’t just about making something that looks cool; every angle, every cutout, and every screw hole is meticulously planned. During this phase, engineers run powerful simulations called Finite Element Analysis (FEA). This software applies virtual forces to the 3D model—simulating motor thrust, crash impacts, and aerodynamic drag—to identify potential weak spots. The design is then tweaked and optimized to be as strong and light as possible.

Precision Cutting: The Role of CNC Machining

Unlike plastic parts that are often molded, the components of a drone frame are cut from large, flat sheets of cured carbon fiber. This is where the Computer Numerical Control (CNC) machine comes in. The digital files from the CAD program are fed into the CNC router, which uses a high-speed cutting bit to precisely carve out each part—the top plate, bottom plate, and arms. This automated process ensures that every piece is perfectly identical and accurate to within a fraction of a millimeter, guaranteeing a perfect fit during assembly.

Finishing Touches for Durability

Once the parts are cut, they undergo a crucial finishing step: chamfering. A special bit is used to bevel the sharp, 90-degree edges of the carbon fiber. This isn’t just for looks. A chamfered edge makes the part significantly more durable and resistant to delamination (where the layers of carbon fiber start to separate) upon impact. High-quality frames will almost always have this feature. The parts are then cleaned and sometimes given a clear coat for a glossy finish.

Assembly: Bringing It All Together

The final step is assembly. The precisely cut carbon fiber parts are joined together using high-grade hardware, which typically includes lightweight aluminum standoffs and strong steel screws. The result is a rigid, perfectly aligned chassis ready to be fitted with motors, electronics, and a camera—the foundation of a high-performance flying machine.

Part 6: A User’s Guide: Choosing, Maintaining, and Repairing Your Frame

As a drone pilot, understanding the nuances of your carbon fiber frame will help you make better purchasing decisions and keep your aircraft in top condition. Here’s some practical advice from years of building and flying.

Choosing the Right Carbon Fiber Frame

- Weave: For 99% of pilots, a Twill Weave is the best choice. It provides the ideal balance of multi-directional strength and manufacturability, and it’s the industry standard for a reason.

- Thickness: This is a critical balancing act between durability and weight.

- Racing Drones: Look for arms that are 4mm to 5mm thick. This offers good crash resistance without being too heavy.

- Freestyle Drones: These take a lot of abuse. Arms in the 5mm to 6mm range are common, providing maximum durability for practicing tough tricks.

- Cinematic/Long-Range Drones: Here, weight savings are key. Thinner arms (4mm) might be used to maximize flight time, as these drones are less likely to be crashed hard.

- Plates: Top and bottom plates are typically between 1.5mm and 2.5mm thick.

- Finishing: Always look for a frame with chamfered edges. It’s a sign of quality manufacturing and will make your frame last much longer.

Maintenance and Inspection Best Practices

After every few sessions, and especially after a crash, give your frame a quick inspection:

- Check for Delamination: Look at the edges of the arms and plates. If you see whitish stress marks or feel the layers starting to separate, that’s delamination.

- Look for Cracks: Pay close attention to high-stress areas, like where the arms meet the body and around the motor mounting screws. A small crack can quickly become a complete failure in the air.

- Tighten Your Screws: Vibrations can loosen screws over time. Give them a quick check to make sure everything is snug (but don’t overtighten and strip them!).

The Big Question: Can You Repair a Broken Frame?

This is a question I hear all the time. The short, honest answer is: for a structural part like a broken arm, you should not repair it. While you can try to glue it back together with epoxy, the repaired joint will create a massive weak spot. It will never have the original strength and is almost guaranteed to fail under stress, likely causing an even worse crash. The only safe solution for a broken arm or main plate is to replace it.

However, for minor issues, a small fix is possible. If you have some edge delamination, you can work a bit of thin CA (super) glue into the separation. This will help seal the fibers and prevent the damage from spreading. But again, for any actual cracks or breaks, replacement is the way to go.

| Frame Type | Typical Arm Thickness | Key Priority | Recommended Features |

|---|---|---|---|

| FPV Racing | 4mm – 5mm | Agility & Moderate Durability | Chamfered Edges, Replaceable Arms |

| Freestyle | 5mm – 6mm | Maximum Durability | Thick Arms, Strong Center Body |

| Cinematic / Long-Range | 4mm – 5mm | Light Weight & Efficiency | Minimalist Design, Optimized for Low Drag |

Part 7: The Downsides: Addressing the Disadvantages of Carbon Fiber

No material is perfect, and it’s important to have a balanced view. While carbon fiber’s advantages are overwhelming, there are a few drawbacks that every drone pilot and builder should be aware of.

The High Cost

There’s no getting around it: carbon fiber is an expensive material. The complex, energy-intensive process required to produce it makes it significantly more costly than raw aluminum or plastic. This higher material cost is reflected in the final price of a high-quality drone frame.

Brittleness to Sharp Impacts

While carbon fiber is incredibly strong and handles blunt impacts well, it can be brittle when it comes to sharp, focused impacts. Hitting the flat side of a concrete wall might just scuff the frame, but hitting a sharp metal corner or a steel pole could cause the carbon to fracture or shatter. This is a different failure mode than aluminum, which would likely just bend or dent.

Electrical Conductivity: A Hidden Danger

This is a critical technical challenge that catches many new builders by surprise. Carbon fiber conducts electricity. This means if a live wire with damaged insulation, a motor wire, or a component leg touches the frame, it can cause a catastrophic short circuit that can instantly destroy your flight controller, ESC, or other electronics. It is absolutely essential to ensure all electronic components are properly insulated and that no exposed wires can rub against the frame during flight.

Part 8: The Future of Drone Frames: Innovation in Materials

The world of materials science never stands still. While carbon fiber is the current king, researchers and manufacturers are constantly experimenting with new technologies to push the performance envelope even further.

Hybrid Composites

We are starting to see frames that aren’t 100% carbon fiber. Designers are experimenting with hybrid composites, blending layers of carbon fiber with other materials like Kevlar or fiberglass. The goal is to get the best of both worlds: the incredible stiffness of carbon fiber combined with the superior impact toughness of a material like Kevlar. This could lead to frames that are even more resistant to breaking from sharp impacts.

3D Printed Carbon Fiber

The rise of advanced 3D printing is a game-changer. We now have filaments that are reinforced with chopped carbon fibers (like Nylon-CF). While these materials are not yet as strong or stiff as the traditional woven carbon fiber sheets, they open up a world of design possibilities. 3D printing allows for the creation of complex, organic, and highly aerodynamic shapes—like a single-piece monocoque body—that would be impossible to make with flat sheets. As this technology matures, we may see it used for more structural components.

Part 9: Conclusion – Why Carbon Fiber Will Continue to Soar

The evidence is clear. From its fundamental atomic structure to its real-world performance in the air, carbon fiber provides a combination of properties that seems tailor-made for the demands of modern drones. Its phenomenal strength-to-weight ratio allows for longer flights and greater agility. Its extreme rigidity provides the stable, vibration-free platform necessary for professional results. And its durability ensures that our aircraft can withstand the rigors of flight.

While it may be more expensive and present a few technical challenges, its core benefits directly solve the most critical engineering problems in drone design. As drone technology continues its rapid evolution, pushing for greater speeds, longer endurance, and heavier payloads, carbon fiber will undoubtedly remain the essential material that allows these incredible machines to take flight and reach for new heights.

Part 10: FAQ (Frequently Asked Questions)

Q1: Is a thicker carbon fiber drone frame always better?

Not necessarily. While a thicker frame (e.g., 6mm arms vs. 5mm arms) is undoubtedly more durable and less likely to break in a crash, it’s also heavier. This extra weight requires more power from the motors, which can reduce flight time and make the drone feel less agile. The best thickness is a trade-off: choose thicker arms for aggressive freestyle flying where you expect hard crashes, and opt for a slightly thinner, lighter frame for racing or long-range flying where performance and efficiency are the top priorities.

Q2: Why do my carbon fiber drone arms have rounded or beveled edges?

This is a premium finishing process called chamfering. A sharp, 90-degree edge on a carbon fiber part is a weak point that is prone to splitting and delaminating on impact. By rounding or beveling that edge, the force of an impact is distributed more evenly, making the arm significantly more durable. It’s a key feature to look for in a high-quality drone frame.

Q3: Is carbon fiber waterproof?

Yes, the cured carbon fiber composite itself is completely waterproof. It does not absorb water and will not rust or corrode like metal. This makes the frame material ideal for flying in humid or wet conditions. However, it is very important to remember that the electronic components on the drone (flight controller, ESCs, camera, etc.) are almost always not waterproof unless they have been specifically treated with a conformal coating.

Q4: Can carbon fiber block my radio or GPS signals?

Yes, absolutely. Carbon fiber is very effective at blocking radio frequency (RF) signals, including the 2.4GHz or 5.8GHz signals from your radio controller and the signals from GPS satellites. This is why proper antenna placement is critical. You must always mount your radio receiver antennas so that the active elements extend away from the carbon fiber frame, giving them a clear line of sight to your transmitter. Similarly, a GPS module should be mounted on a mast that raises it above the main body of the frame.

Q5: I see frames advertised as “T300” or “T700” carbon. What does that mean?

These are grade designations for carbon fiber raw materials, originally from a manufacturer called Toray Industries. T700 is generally considered a higher-performance grade than T300, offering greater tensile strength and stiffness. While many excellent frames are made from high-quality T300-equivalent carbon, manufacturers of premium, top-tier frames will often advertise their use of T700 carbon as a mark of superior material quality and performance.