In simple terms, carbon fiber is a polymer, sometimes known as graphite fiber, that is incredibly strong and remarkably lightweight. It is made of thin crystalline filaments of carbon that are twisted together and woven into a fabric, which is then combined with a resin to create a final, rigid composite material. This guide explores every facet of this “wonder material,” from its microscopic structure to its revolutionary impact on industries like aerospace and automotive. We will delve into its history, unpack the complex manufacturing process, compare its remarkable properties to those of materials like steel and aluminum, and examine the challenges and future innovations that lie ahead. Ultimately, you will understand why carbon fiber’s unique ability to be both strong and light makes it one of the most important advanced materials of our time.

Table of Contents

Introduction – More Than Just a Black Weave

Throughout history, certain materials have defined human progress. Steel gave us skyscrapers and mighty bridges. Aluminum gave us the age of aviation. Today, we are in the era of a new wonder material, one that is pushing the boundaries of what’s possible in nearly every field of engineering: carbon fiber.

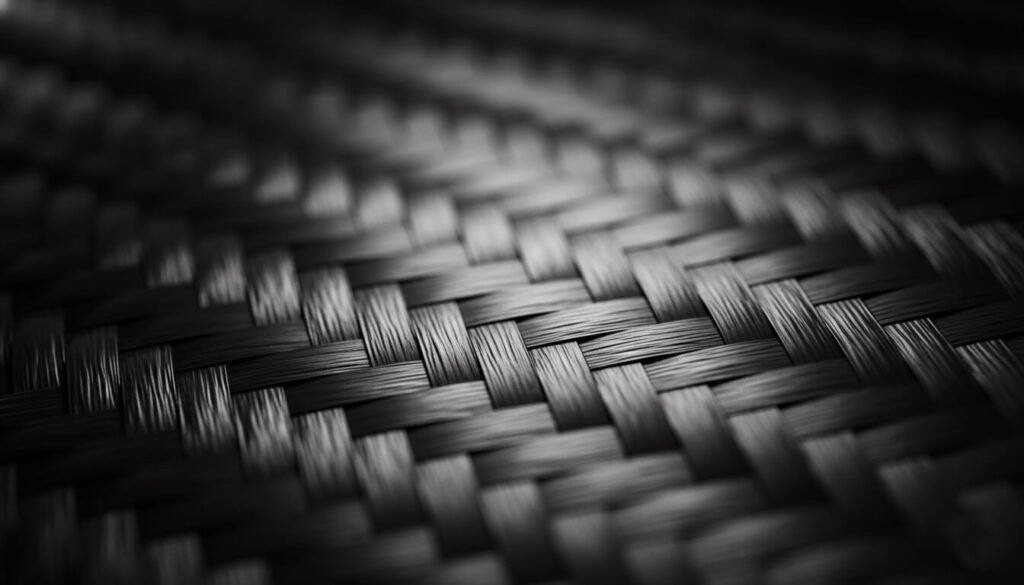

You’ve seen it on high-end sports cars, state-of-the-art aircraft, and professional sporting equipment. It’s the sleek, black, woven material that has become a symbol of high performance and cutting-edge technology. But what is it, really? How can something so lightweight be stronger than steel?

This guide is designed to be your definitive resource, providing a deep and comprehensive answer to the question, “What is carbon fiber?” We will journey from its atomic structure to the global industries it’s transforming. We will uncover its fascinating history, demystify its complex manufacturing process, explore its incredible properties, and showcase its real-world applications. By the end, you will not only understand what carbon fiber is but also appreciate why it has become the material of choice for shaping our future.

Defining Carbon Fiber: The Three Distinct Forms

One of the most common points of confusion is that the term “carbon fiber” can refer to three different things. Understanding each form is the key to grasping the whole concept.

The Filament: The Microscopic Foundation

At its absolute most basic level, carbon fiber starts as a collection of microscopic filaments. Each filament is a tiny, hair-like strand of nearly pure carbon atoms, measuring just 5 to 10 micrometers in diameter—that’s about eight times thinner than a human hair! The magic lies in their internal structure. The carbon atoms are bonded together in crystals that are aligned along the length of the filament. This highly ordered, parallel alignment is the source of the fiber’s incredible strength.

The Textile: Weaving Strength Together

A single filament, while strong for its size, isn’t very useful on its own. To build anything substantial, thousands of these individual filaments are bundled together into a kind of super-thread called a “tow.” This tow can then be used directly in processes like filament winding or, more commonly, woven on a loom to create a fabric sheet. This woven textile is the classic carbon fiber material that most people recognize, with its distinct and often beautiful patterns.

The Composite: The Final High-Performance Material

Carbon fiber fabric on its own is like cloth—it has strength when you pull on it, but it’s flimsy. To turn it into a hard, structural component, it must become a composite. This is the final form used in products and is more accurately called Carbon Fiber Reinforced Polymer (CFRP).

To create CFRP, the carbon fiber fabric is impregnated with a liquid polymer matrix, most commonly an epoxy resin. This is then placed into a mold and subjected to heat and pressure, which cures the resin and hardens it into a solid shape. The result is a material where the carbon fibers provide the strength and stiffness, while the resin matrix holds them in place, protects them, and distributes the load across the entire structure. Think of it like reinforced concrete: the carbon fibers are the steel rebar, and the epoxy resin is the concrete.

The Genesis of a Wonder Material – A Rich History

The story of carbon fiber is a fascinating journey of scientific curiosity and engineering innovation, stretching back over 150 years.

The Humble Beginnings: Filaments for Light Bulbs

The very first carbon fibers weren’t made for race cars or airplanes, but to light up the world. In 1860, English physicist Joseph Swan produced carbon fibers for use in an early light bulb. A few years later, in 1879, American inventor Thomas Edison developed a more reliable version by baking cotton threads or bamboo slivers at high temperatures. This process, called carbonization, turned the organic material into a pure carbon filament that could glow brightly when heated by electricity. These early fibers were brittle, but they were the pioneers.

The Breakthrough Moment: Dr. Roger Bacon’s “Graphite Whiskers”

The modern era of high-performance carbon fiber began with a chance discovery in 1958 at the Union Carbide Parma Technical Center in Ohio. A physicist named Dr. Roger Bacon was studying graphite at very high temperatures and pressures. He noticed that when he broke open the graphite deposits, he found what he called “graphite whiskers.”

These were perfect filaments of graphite, incredibly thin yet astonishingly strong and stiff. Bacon had created the first true high-performance carbon fibers. However, the process was wildly impractical for mass production; he estimated the cost to be around $10 million per pound! The potential was clear, but the challenge was now to find a cheap and efficient way to make them.

The Evolution of Precursors: Rayon, PAN, and Pitch

The key to making affordable carbon fiber lay in finding the right starting material, or “precursor.”

- The Rayon Era (1960s): Researchers soon turned to rayon, a cellulose-based polymer. By heating and stretching rayon fibers, they were able to create the first commercially viable carbon fibers. These were strong enough to be used by the U.S. Air Force for rocket nozzles and heat shields.

- The Rise of PAN (Polyacrylonitrile): The true revolution came in the early 1960s. A process developed in Japan by Dr. Akio Shindo, using a polymer called polyacrylonitrile (PAN) as the precursor, produced carbon fibers with far superior strength and stiffness. British researchers refined this process, and soon Japanese companies like Toray Industries took the lead in manufacturing. Today, over 90% of all carbon fiber is made from PAN.

- The Pitch-Based Innovation: In the 1970s, another precursor was developed from petroleum pitch, a byproduct of oil refining. Pitch-based fibers are unique because they can be made incredibly stiff and are excellent at conducting heat, making them perfect for specialized uses like satellites, aircraft brakes, and electronic heat sinks.

The Art and Science of Manufacturing

Creating carbon fiber is a highly controlled, multi-stage process that is part chemical engineering and part mechanical precision. It’s a journey that transforms a simple polymer thread into one of the most advanced materials on Earth.

The Precursor: Starting with a Polymer Thread

As we learned, the process almost always begins with the precursor, polyacrylonitrile (PAN). This raw material is a polymer in the form of a white powder. The journey starts by turning this powder into long, continuous threads.

The Manufacturing Process in Five Key Stages

- Spinning: The PAN powder is mixed with other ingredients and dissolved into a chemical solvent to create a thick liquid. This liquid is then extruded through tiny nozzles, called spinnerets, into a chemical bath or air chamber that causes it to solidify into long fibers. These fibers are then washed and stretched to several times their original length to start aligning the polymer molecules.

- Stabilizing (Oxidation): This is a crucial step to prepare the fibers for the intense heat to come. The white PAN fibers are slowly pulled through heated ovens in the presence of air, at temperatures between 200-300°C. This process causes the fibers to take in oxygen atoms, which rearranges their internal atomic structure from a straight chain into a more stable “ladder” structure. This prevents the fibers from simply melting in the next stage.

- Carbonizing: Now the stabilized, dark-colored fibers are ready to become carbon. They are moved into a series of furnaces, each hotter than the last, filled with an inert (oxygen-free) gas mixture. Heated to temperatures often exceeding 1,000°C, the intense energy causes the atoms within the fibers to vibrate violently. This vibration shakes loose and expels almost all non-carbon atoms (like hydrogen and nitrogen). What’s left behind is a fiber composed of long, tightly interlocked chains of pure carbon atoms.

- Surface Treatment: The carbonized fibers are incredibly strong but have a very smooth surface, which doesn’t bond well with the resins used to make composites. To fix this, the fibers undergo a surface treatment, often an electrolytic bath. This process slightly etches the surface and adds oxygen molecules, creating better mechanical and chemical bonding sites for the resin.

- Sizing: Finally, the fibers are coated with a thin protective layer called “sizing.” This coating, which can be epoxy, polyester, or another polymer, protects the delicate fibers from damage during the final weaving and winding process. The sized fibers are then wound onto bobbins, ready to be woven into fabric or used to create a final composite part.

Decoding the Properties: What Makes Carbon Fiber So Special?

Carbon fiber’s popularity isn’t just hype; it’s based on a set of truly remarkable physical properties that set it apart from traditional materials. Let’s break down exactly what makes it the material of choice for high-performance applications.

The Signature Trait: High Strength-to-Weight Ratio

This is the headline feature and the most important property of carbon fiber. It is a material that is both incredibly strong and incredibly light. How strong? A high-quality carbon fiber composite can be five times stronger than steel and twice as stiff, all while being up to five times lighter. This combination is the holy grail for engineers in any industry where weight is a penalty.

| Property | Carbon Fiber (Standard) | Aluminum (6061) | Titanium (Ti-6Al-4V) | Steel (4130) |

|---|---|---|---|---|

| Density (g/cm³) | ~1.8 | 2.7 | 4.5 | 7.85 |

| Tensile Strength (MPa) | ~3500 | ~310 | ~950 | ~670 |

| Stiffness (GPa) | ~230 | ~69 | ~114 | ~205 |

In the real world, this means a car part made from carbon fiber can provide the same strength as a steel part at a fraction of the weight, leading to better fuel efficiency and faster acceleration. In aerospace, it means an aircraft can fly farther on less fuel.

High Stiffness (Young’s Modulus): Resisting Deformation

Stiffness is a material’s ability to resist bending or flexing when a force is applied. Carbon fiber is exceptionally stiff. This is crucial for applications that demand precision and stability. For example, a stiff bicycle frame transfers more of the rider’s energy directly to the wheels without being wasted on frame flex. A stiff aircraft wing maintains its optimal aerodynamic shape under the immense forces of flight, improving efficiency and control.

Superior Durability and Fatigue Resistance

Durability isn’t just about surviving a single impact; it’s about withstanding repeated stress over a long lifetime. Materials, especially metals, can suffer from “fatigue,” where they weaken and eventually fail after thousands of cycles of being loaded and unloaded. Carbon fiber has exceptional fatigue resistance. A carbon fiber component can endure the constant vibrations and stresses of a race car or an airplane for much longer than an equivalent metal part without degrading.

Corrosion and Chemical Resistance

Unlike steel or aluminum, carbon fiber is a polymer composite. It does not rust. This makes it an ideal material for use in harsh environments, such as marine applications where saltwater would quickly corrode metals. It is also highly resistant to a wide range of chemicals, adding to its longevity.

One important note is the potential for galvanic corrosion. When carbon fiber is in direct contact with some metals (especially aluminum) in the presence of an electrolyte like saltwater, it can act like a battery and accelerate the corrosion of the metal. For this reason, designers often use a non-conductive barrier, like a layer of fiberglass, between carbon fiber and metal parts.

Low Thermal Expansion and High-Temperature Tolerance

Most materials expand when they get hot and shrink when they get cold. Carbon fiber has a very low Coefficient of Thermal Expansion (CTE), meaning it holds its shape and size remarkably well across a wide range of temperatures. This dimensional stability is critical for precision applications like satellite components, telescopes, and high-tech manufacturing tools that must remain accurate to the micron, regardless of the temperature.

Understanding the Weaves and Grades

Not all carbon fiber is created equal. The way the fibers are woven and the specific type of fiber used can be tailored to achieve different properties for different applications. Understanding these variations is key to appreciating the material’s versatility.

The Weave: Dictating Form and Function

The visual pattern of carbon fiber isn’t just for looks; it’s a direct result of the weaving style, which affects both the strength and flexibility of the fabric.

- Plain Weave: This is the simplest pattern, a classic one-over, one-under checkerboard. This tight weave makes the fabric very stable and easy to handle, but it’s not very flexible, so it’s best suited for flat sheets or simple curves.

- Twill Weave: This is the iconic diagonal pattern that most people associate with carbon fiber. In a twill weave, each tow passes over two other tows and then under two (2×2 twill). This longer “float” makes the fabric much more pliable and able to conform to complex shapes and curves. It offers an excellent balance of stability and flexibility, making it the most popular weave for automotive and sporting goods.

- Satin Weave: Satin weaves have even longer floats (e.g., a tow goes over four other tows and under one). This makes the fabric extremely drapable and gives it a very smooth, almost seamless finish. It’s ideal for wrapping around very complex shapes but is the least stable of the weaves.

K-Grades Explained: 1K, 3K, 12K

You will often see carbon fiber described with a “K” number, such as “3K twill.” This number refers to the number of individual carbon filaments in each tow (the bundle of threads). The “K” stands for one thousand.

- 1K: Each tow contains 1,000 filaments.

- 3K: Each tow contains 3,000 filaments. This is arguably the most common grade for consumer products.

- 6K: Each tow contains 6,000 filaments.

- 12K: Each tow contains 12,000 filaments.

A lower K-count like 1K or 3K results in a fabric with a tighter, finer-looking weave. A higher K-count like 12K has a larger, chunkier-looking weave and is often used for making thicker, structural parts more quickly.

Performance Grades: Standard to Ultra-High Modulus

Beyond the weave, the carbon fibers themselves are classified by their mechanical properties, particularly their stiffness (modulus). Different applications demand different levels of performance.

| Grade Type | Tensile Modulus (Stiffness) | Common Applications |

|---|---|---|

| Standard Modulus (HT) | 200-280 GPa | Sporting goods, automotive, industrial applications |

| Intermediate Modulus (IM) | 280-350 GPa | High-performance aerospace, racing, pressure vessels |

| High Modulus (HM) | 350-600 GPa | Satellites, military aircraft, premium F1 components |

The Real World – Applications Across Industries

Carbon fiber’s unique blend of properties has allowed it to revolutionize a staggering range of industries. What began as a niche aerospace material is now found in products all around us.

Aerospace & Defense

This was the first industry to truly embrace carbon fiber, and for good reason. In aerospace, weight is directly tied to fuel consumption and performance. Modern airliners like the Boeing 787 Dreamliner and the Airbus A350 have fuselages and wings made of over 50% composite materials, leading to massive fuel savings. In defense, carbon fiber is used for everything from fighter jets and drones to lightweight helmets and body armor.

Automotive & Motorsports

The quest for speed is a quest for lightweighting. Formula 1 racing was an early adopter, using carbon fiber to build the ultra-strong, ultra-light “monocoque” chassis that protects the driver. Today, that technology has trickled down to high-end hypercars from manufacturers like McLaren, Bugatti, and Koenigsegg, who use it for everything from body panels to wheels. As costs come down, it’s becoming more common in mass-produced cars to improve efficiency.

Sporting Goods

For athletes, lighter and stiffer equipment means a competitive edge. Carbon fiber has transformed the world of sports. It’s used to make:

- Bicycle frames that are both feather-light for climbing and incredibly stiff for sprinting.

- Tennis rackets that allow for faster swing speeds and more power.

- Golf club shafts that are lighter and stronger than steel.

- Skis and snowboards that are more responsive and better at absorbing vibrations.

- High-performance boat hulls, masts, and even the shells for competitive rowing.

Wind Energy

To capture more wind and generate more electricity, wind turbine blades need to be longer and longer. Making a 150-foot blade out of traditional materials would make it incredibly heavy and inefficient. Carbon fiber is used to create the structural “spar,” or backbone, inside these massive blades, giving them the necessary stiffness to withstand immense forces without adding crippling weight.

The Challenges and Limitations

Despite its “wonder material” status, carbon fiber is not without its challenges. A balanced understanding requires looking at its downsides, which are primarily related to cost, impact behavior, and environmental concerns.

The Cost Factor: Why is Carbon Fiber So Expensive?

The single biggest barrier to the widespread adoption of carbon fiber is its cost. Compared to steel or aluminum, it can be 10 to 12 times more expensive. This high price tag stems from several factors:

- Raw Materials: The precursor polymer, PAN, is a specialty chemical that is more expensive to produce than raw ore for metals.

- Energy-Intensive Process: The carbonization stage requires extremely high temperatures, consuming a vast amount of energy.

- Complex Manufacturing: The overall process is slow and requires precise control, making it less suitable for high-volume, low-cost production compared to stamping a piece of steel.

Brittleness and Impact Damage

While carbon fiber is incredibly strong and stiff, it behaves differently from metal when it fails. A metal part will often bend or deform when overloaded, giving a visible warning of damage. Carbon fiber, on the other hand, is more brittle. When it reaches its limit, it can fail suddenly and catastrophically, fracturing or shattering. This is a major consideration for engineers, especially in applications where impacts are likely. Furthermore, it can suffer from “Barely Visible Impact Damage” (BVID), where a low-speed impact can cause internal damage (delamination) with little to no sign on the surface.

The Recycling Conundrum

This is one of the most significant challenges facing the composites industry today. Traditional carbon fiber composites, made with thermoset epoxy resins, are very difficult to recycle. Once the resin is cured, it cannot be simply melted down and reformed. The most common recycling method is pyrolysis, a process that uses high heat to burn off the resin, leaving the carbon fibers behind. However, this process is energy-intensive, and the recovered fibers are often shorter and have reduced mechanical properties compared to virgin fibers.

The Future of Carbon Fiber

The world of carbon fiber is constantly evolving. Researchers and companies around the globe are working to overcome its limitations and unlock even greater potential.

Driving Down Costs

A major focus of research is on reducing the cost of production. This includes developing lower-cost precursor materials, such as lignin (a byproduct of the paper industry), and creating more energy-efficient conversion processes. Facilities like the Department of Energy’s Carbon Fiber Technology Facility (CFTF) are dedicated to finding ways to make carbon fiber affordable for mass-market applications, like everyday passenger cars.

A Circular Economy: Innovations in Recycling

The sustainability challenge is being met with exciting innovations. New types of resins, known as vitrimers, are being developed. These are thermosetting polymers that behave like a traditional epoxy but can be reshaped and repaired with the application of heat, opening the door to true recyclability. As these technologies mature, we will move closer to a circular economy for composite materials.

The Next Frontier: Carbon Nanotubes and Graphene

Looking even further ahead, scientists are working with even stronger forms of carbon. Carbon nanotubes—hollow cylinders of carbon atoms—are considered one of the strongest materials ever discovered. Blending these nanotubes with traditional carbon fibers could create next-generation composites with properties that are orders of magnitude better than what we have today.

Conclusion – A Material Defining Our Future

From its humble beginnings as a glowing filament in a light bulb, carbon fiber has evolved into one of the most critical high-performance materials of the modern era. It is a composite material defined by a combination of properties that once seemed impossible: the strength of steel at the weight of plastic. Its journey is a testament to decades of scientific innovation and engineering prowess.

While challenges of cost and sustainability remain, the relentless push for efficiency, speed, and performance ensures that the demand for carbon fiber will only grow. It is the material that allows us to fly farther, drive faster, and harness renewable energy more effectively. As we continue to innovate, carbon fiber will undoubtedly remain at the forefront, building a lighter, stronger, and more advanced future.

FAQ (Frequently Asked Questions)

Q1: In simple terms, what is carbon fiber?

In simple terms, carbon fiber is a super-strong, ultra-lightweight material. Think of it as fabric made from incredibly thin carbon threads, which is then hardened with a plastic-like resin to create a solid, rigid shape. This final material is used to make high-performance products where both strength and low weight are critical.

Q2: Is carbon fiber really stronger than steel?

Yes, when you compare them by weight, carbon fiber is significantly stronger. A typical carbon fiber composite can be up to five times stronger than steel and twice as stiff, while being about two-thirds lighter. This is why it’s the preferred material for applications like race cars and aircraft.

Q3: Why is carbon fiber so expensive?

The high cost is due to a multi-step, energy-intensive manufacturing process. It starts with an expensive raw material (a polymer called PAN), which then goes through several stages of precise heating and chemical treatments. The specialized equipment and high energy consumption required for this process contribute to its high price compared to mass-produced metals.

Q4: Can carbon fiber be repaired if it breaks?

Yes, but it’s a complex process. Unlike metal that can be welded, repairing carbon fiber requires specialized techniques to patch the damaged area and restore its structural integrity. For many consumer products, especially those with critical structural roles like a bicycle frame, replacement of the part is often safer and more common than repair.

Q5: Can carbon fiber be recycled?

Traditional carbon fiber composites are difficult and expensive to recycle. The process involves burning or chemically dissolving the resin to recover the carbon fibers. However, the industry is rapidly developing new recycling technologies and even new types of resins that will make carbon fiber more sustainable and part of a circular economy in the future.

Q6: What is the difference between “carbon fiber” and “carbon fibre”?

There is no difference in the material itself. The difference is simply in the spelling. “Carbon fiber” is the American English spelling, while “carbon fibre” is the British English spelling. Both terms refer to the exact same material.