Carbon fiber sheets are remarkable materials that are transforming industries from aerospace to your garage. They are incredibly strong—five times stronger than steel—yet astonishingly lightweight, making them perfect for high-performance applications. This guide will walk you through everything you need to know, from the fascinating history of this “super material” and how it’s made, to its diverse types, technical properties, and practical uses. Whether you’re an engineer, a hobbyist, or just curious, you’ll discover why carbon fiber is a cornerstone of modern innovation and how you can use it for your next big project.

Table of Contents

The Story of Carbon Fiber: From Light Bulbs to Supercars

The journey of carbon fiber is a tale of scientific curiosity and industrial demand. It wasn’t born in a high-tech lab for race cars; its roots trace back to a much humbler, yet brilliant, invention.

A Brief History

Believe it or not, the story starts with the light bulb. In the 19th century, British chemist Sir Joseph Swan experimented with carbon filaments for his early incandescent lamps. These were the first-ever carbon fibers! However, the modern era of high-strength carbon fiber truly began in the late 1950s and early 1960s. The aerospace and defense industries were hungry for materials that were both incredibly strong and exceptionally light. Early experiments involved carbonizing rayon fibers, which led to the creation of the first high-performance carbon fibers suitable for military aircraft and even sports equipment. By the 1960s, companies like Union Carbide were pioneering commercial production, setting the stage for a materials revolution.

What is Carbon Fiber Actually Made Of?

At its core, carbon fiber is exactly what its name suggests: fibers made almost purely of carbon atoms. These atoms are bonded together in microscopic crystals aligned in long chains, which gives the fiber its incredible strength.

- Raw Materials: The journey begins with a precursor material. Today, over 90% of all carbon fiber is made from a polymer called polyacrylonitrile (PAN). In some special cases, a substance called pitch is used to create fibers with even higher stiffness.

- The Matrix (Resin): Raw carbon fiber threads are like uncooked spaghetti—strong in one direction but floppy and useless on their own. To create a rigid, usable sheet, these fibers must be embedded in a supportive matrix, which is typically an epoxy resin. The fabric is saturated with this resin and then cured (hardened with heat), creating a solid, durable composite material. This final product is what we know as a carbon fiber sheet.

Understanding the “K” System: A Quick Guide

When you shop for carbon fiber, you’ll see terms like “1K,” “3K,” or “12K.” This isn’t jargon meant to confuse you. It’s a simple system that tells you about the fiber’s construction. Think of it like the thread count for bed sheets.

- Tow: Carbon fibers are bundled together into something called a “tow,” which is like a yarn.

- The “K” Number: The number before the “K” tells you how many thousands of individual filaments are in that tow.

- 1K: 1,000 filaments per tow. Finer, lighter, and often used for cosmetic layers.

- 3K: 3,000 filaments per tow. This is the most common and recognizable type, giving carbon fiber its classic woven, slightly checkered appearance. It offers a great balance of strength, weight, and cost.

- 6K & 12K: 6,000 and 12,000 filaments per tow, respectively. These are heavier, with a larger weave pattern, and are often used for thicker structural parts.

How Are Carbon Fiber Sheets Manufactured?

Creating carbon fiber sheets is a sophisticated, multi-step process that turns a simple polymer into one of the world’s strongest materials. It’s a journey of intense heat and precise chemistry.

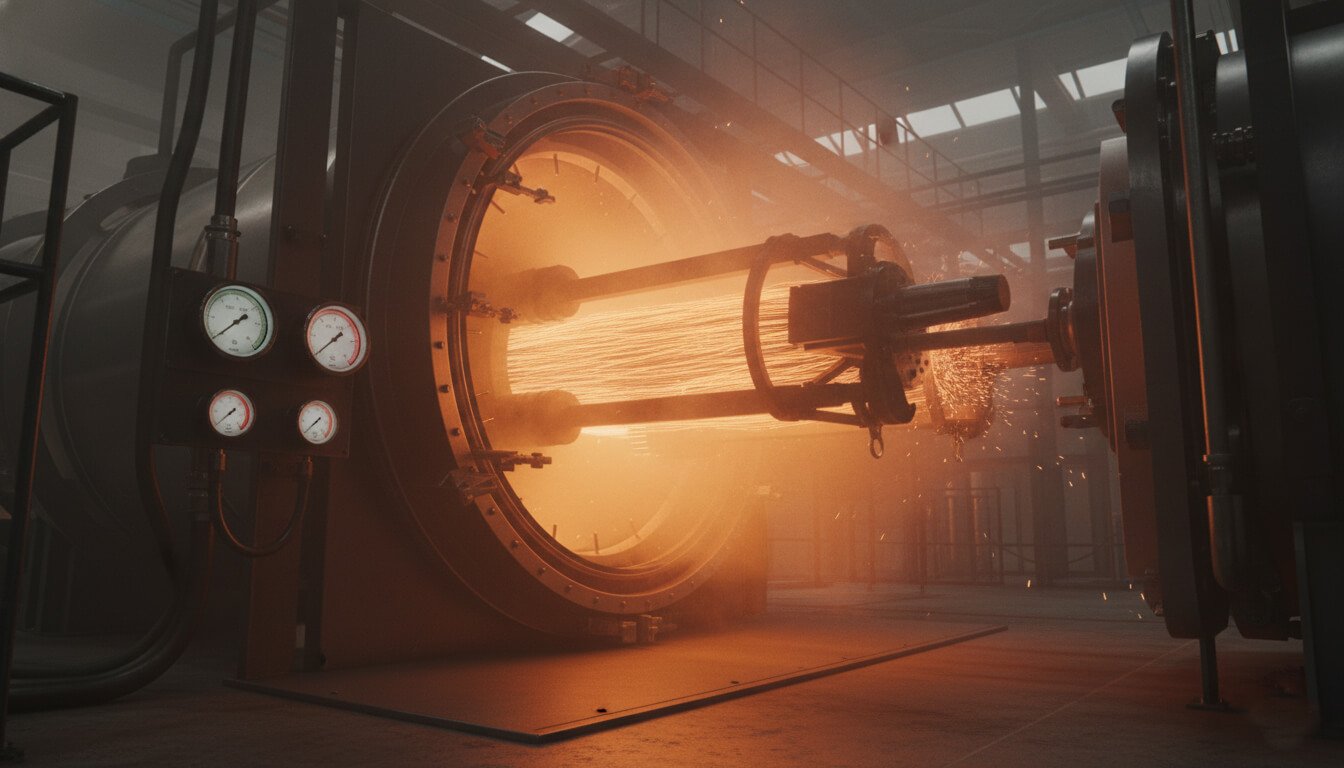

The Fiber Creation Process (The Precursor Stage)

It all starts with the precursor, usually PAN. This raw material undergoes a series of transformations to become pure carbon fiber.

- Spinning: The PAN polymer is spun into long, thin fibers, similar to how textiles are made.

- Stabilizing: The fibers are heated in an oxygen-rich environment. This crucial step alters their atomic bonding, preparing them to withstand the intense heat to come without melting.

- Carbonizing: The stabilized fibers are moved into furnaces filled with an inert (oxygen-free) gas and heated to extremely high temperatures. This intense heat burns off almost all non-carbon atoms, leaving behind long, tightly-interlocked chains of pure carbon crystals.

- Surface Treatment: The surface of the newly formed fibers is slightly oxidized. This might sound counterintuitive, but it etches the surface, making it rougher on a microscopic level. This helps the epoxy resin grip the fibers for a much stronger bond.

From Fiber to Fabric to Sheet

Once the raw fibers are created, they are woven into fabrics. Then, this fabric must be combined with resin to form a rigid sheet. There are several ways to do this, each with its own pros and cons.

| Method | Description | Best For |

|---|---|---|

| Wet Layup | Carbon fiber fabric is laid in a mold, and resin is applied manually with a brush or roller. It’s a hands-on, lower-cost method. | DIY projects, one-off parts, and applications where perfect consistency isn’t critical. |

| Vacuum Infusion | Dry fabric is placed in a mold and sealed in a vacuum bag. A vacuum pulls the resin through the fabric, ensuring even distribution and removing air bubbles. | High-quality parts like boat hulls and custom car components. Offers better consistency than wet layup. |

| Prepreg & Autoclave Curing | This is the “gold standard.” The fabric is “pre-impregnated” with a precise amount of resin. Layers are cut and placed in a mold, then cured inside an autoclave—a machine that applies immense heat and pressure. | Aerospace, Formula 1, and high-end applications requiring the absolute best strength-to-weight ratio and flawless quality. |

| Compression Molding | Carbon fiber material (often prepreg) is placed into a heated mold, which is then pressed together under high pressure to form the part. | High-volume production of specific, repeatable shapes. |

Types and Classifications of Carbon Fiber Sheets

Not all carbon fiber sheets are created equal. They come in different weaves, forms, and grades, each designed for a specific purpose. Understanding these differences will help you choose the perfect material for your project.

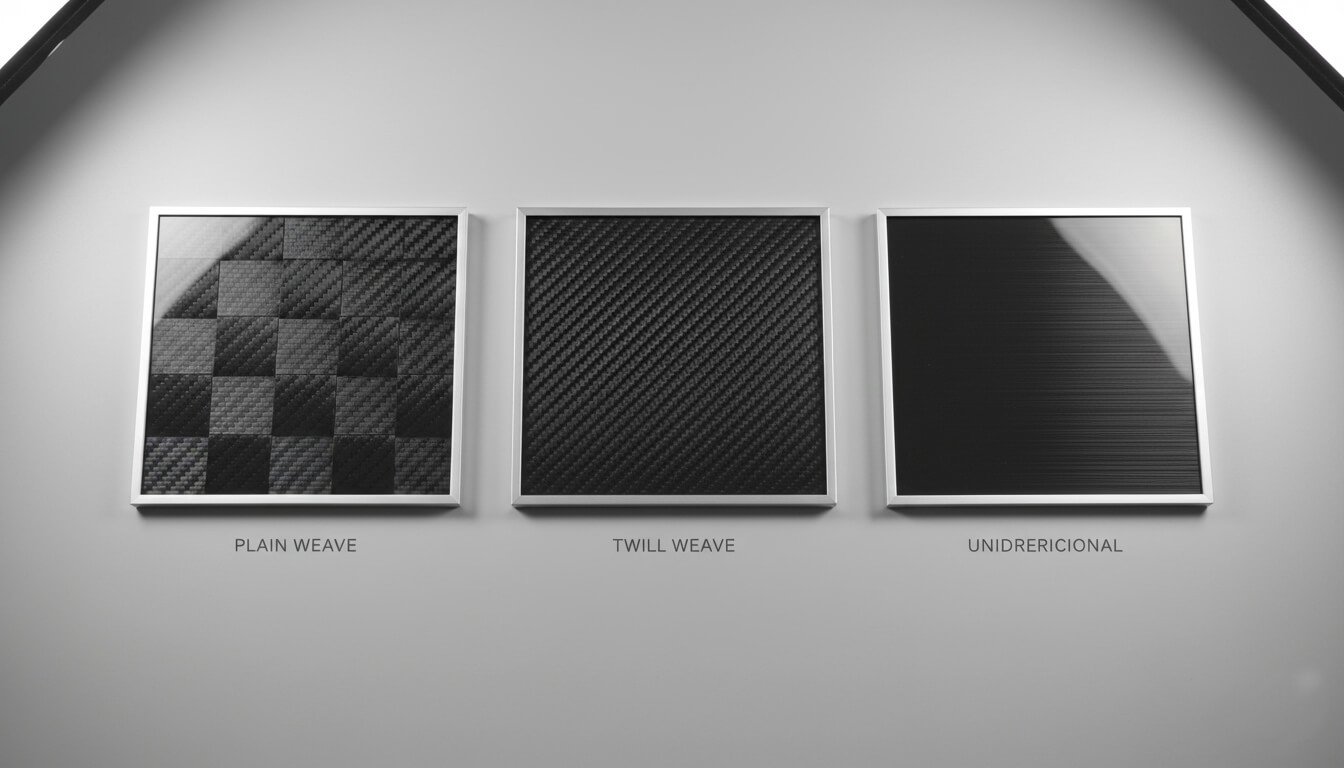

By Weave Pattern: Looks and Performance

The way carbon fibers are woven together affects both the sheet’s appearance and its mechanical properties. The pattern determines how forces are distributed across the material.

- Plain Weave: This is a simple 1×1 over-under pattern, just like a checkerboard. It’s very stable and doesn’t distort easily, but this also makes it a bit harder to drape over complex curves.

- Twill Weave: This weave has a 2×2 over-under pattern, creating a distinct diagonal line. It’s more pliable and easier to form around complex shapes than plain weave. This is the iconic “carbon fiber look” you see on supercars and high-end gear.

- Unidirectional (UD): This isn’t a weave at all. All the fibers are aligned in a single direction. A UD sheet offers incredible strength along the direction of the fibers but is weak in other directions. It’s used for structural applications where the load forces are known and predictable, like in aircraft spars or bicycle frames.

By Product Form: Veneer, Sheet, or Plate?

The thickness of the carbon fiber composite drastically changes its properties and what it can be used for.

| Form | Typical Thickness | Characteristics | Common Uses |

|---|---|---|---|

| Veneer | 0.2mm – 0.5mm | Thin, flexible, and lightweight. Primarily for aesthetics. | Wrapping car dashboards, interior trim, phone cases, and decorative finishes. |

| Sheet | 1mm – 3mm | Ranges from semi-rigid to fully rigid. A good balance of strength and weight. | Drone frames, RC car parts, knife handles, and light structural panels. |

| Plate / Block | 4mm and up | Extremely rigid and strong. Designed for heavy structural loads. | Machining parts, chassis components, structural reinforcement, and industrial tooling. |

Technical Properties: The Science Behind the Strength

What makes carbon fiber so special? It’s a unique combination of properties that few other materials can match. Here’s a breakdown of what makes it a top choice for engineers and designers.

Key Mechanical Properties

- High Tensile Strength: This measures a material’s resistance to being pulled apart. Carbon fiber is exceptionally strong in this regard. A high-quality carbon fiber part can be over 20% stronger than the best fiberglass and many times stronger than steel.

- High Stiffness (Modulus of Elasticity): Carbon fiber is extremely rigid and resistant to bending. This is crucial for applications that need to maintain their shape under stress, like aircraft wings or a race car chassis.

- Low Density (Lightweight): This is carbon fiber’s superpower. For its strength, it is incredibly light. It weighs about 70% less than fiberglass and is significantly lighter than aluminum and steel, which is why it’s so valuable in applications where every gram counts.

Thermal and Electrical Properties

- Conductivity: Yes, carbon fiber is electrically conductive! This is a critical consideration for electronics projects, as a stray piece of carbon dust can short out a circuit board. Its thermal conductivity varies but is generally good at dissipating heat.

- Low Thermal Expansion: Most materials expand when heated and contract when cooled. Carbon fiber has a very low (almost neutral) coefficient of thermal expansion. This means it holds its shape and size extremely well across a wide range of temperatures, a property that is vital for precision instruments and aerospace components.

- Heat Resistance: The carbon fibers themselves can withstand incredibly high temperatures (over 3000°F). However, the heat resistance of a carbon fiber sheet is limited by the resin used. Standard epoxy resins can handle up to around 180°C (356°F), but high-temperature resins are available for more demanding applications.

Material Showdown: Carbon Fiber vs. The Competition

How does carbon fiber stack up against other common materials? Let’s compare.

| Property | Carbon Fiber | Fiberglass | Aluminum | Steel |

|---|---|---|---|---|

| Strength-to-Weight | Exceptional | Good | Very Good | Fair |

| Stiffness | Very High | Moderate | Moderate | High |

| Cost | High | Low | Moderate | Low |

| Corrosion Resistance | Excellent | Excellent | Good | Poor (unless treated) |

| Failure Mode | Brittle (shatters) | Brittle | Ductile (bends) | Ductile (bends) |

Applications and Use Cases: Where is Carbon Fiber Used?

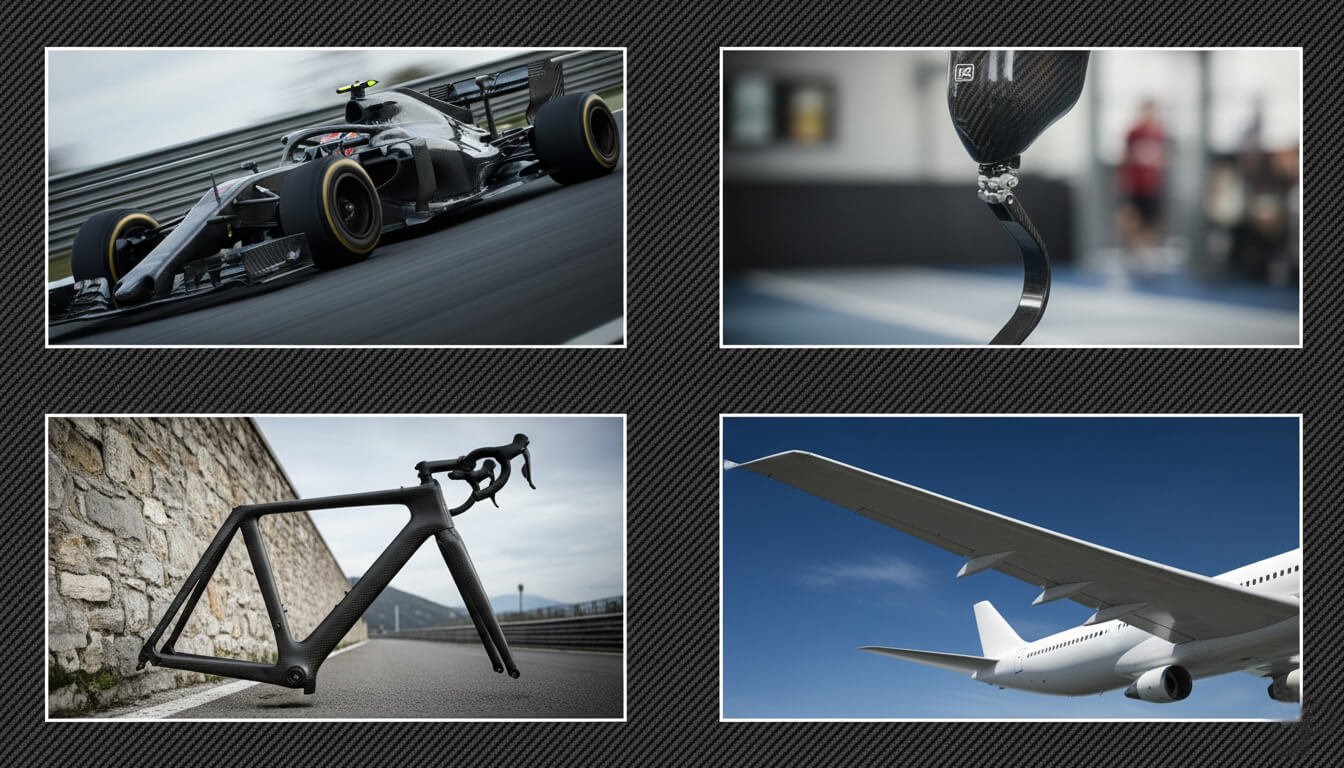

Thanks to its amazing properties, carbon fiber is no longer just for spaceships. It has found its way into nearly every industry, pushing the boundaries of performance and design.

Aerospace & Defense

This is where carbon fiber earned its reputation. Reducing weight is the single most important factor in aviation, as it directly impacts fuel efficiency and payload capacity. It’s used for wings, fuselages, and other critical parts on modern aircraft. In defense, its high strength makes it ideal for reinforcing military vehicles, helmets, and lightweight body armor.

Automotive & Motorsports

In the world of racing, speed is everything. Carbon fiber is used to build the entire chassis (monocoque) of Formula 1 cars, providing incredible rigidity and driver protection at a minimal weight. On production cars, it’s used for body panels, interior trim, and performance parts to reduce weight and improve handling. This also gives luxury cars a high-tech, sporty look.

Sports & Leisure

Athletes are always looking for a competitive edge. Carbon fiber provides it. It makes bicycle frames lighter for faster climbing, tennis rackets stiffer for more powerful shots, and golf club shafts stronger for longer drives. It has revolutionized sports equipment by allowing for designs that are both stronger and lighter than ever before.

Industrial & Medical

In robotics, lightweight carbon fiber arms allow for faster, more precise movements while using less energy. Because carbon fiber is transparent to X-rays (radiolucent), it is an ideal material for medical imaging equipment, like MRI tables, and for manufacturing prosthetic limbs that are both strong and comfortable for the user.

Hobbyist & DIY Projects

Carbon fiber is now more accessible than ever for hobbyists. It’s the material of choice for FPV drone frames, where its rigidity and strength provide crash resistance and stable flight. RC car enthusiasts use it for chassis and suspension parts to improve performance. It’s also popular for making custom items like knife handles, wallets, and phone cases.

Practical Guide: Working with Carbon Fiber Sheets

Working with carbon fiber can be incredibly rewarding, but it requires the right tools, techniques, and—most importantly—safety precautions. It’s not like working with wood or metal.

Safety First: This is a Must-Read

Before you even think about cutting or sanding carbon fiber, you need to understand the risks. The dust created is the primary hazard.

- Carbon Dust is Harmful: The dust consists of tiny, sharp particles that can irritate your skin and, if inhaled, can cause serious lung damage.

- It’s Electrically Conductive: This dust can get into your power tools or electronics and cause them to short out.

Required Personal Protective Equipment (PPE):

- Respirator: A simple paper dust mask is not enough. You need a properly fitted respirator with N95 or P100 cartridges to protect your lungs.

- Gloves: To prevent skin irritation.

- Eye Protection: Safety glasses or goggles are essential.

Cutting Carbon Fiber Sheets

Standard saws or blades designed for wood will be destroyed by carbon fiber almost instantly. It is extremely abrasive. You need tools specifically designed for hard materials.

- Best Tools: A Dremel or rotary tool with a diamond-coated or abrasive cutoff wheel works great for smaller cuts. For straight lines, an angle grinder with a diamond wheel is effective. For industrial or professional results, waterjet cutting is the preferred method as it produces clean edges with no heat or dust.

Drilling and Machining

Drilling carbon fiber requires care to avoid delamination, which is when the layers of the composite split apart.

- Use sharp, new drill bits designed for composites, such as carbide or diamond-tipped bits.

- Drill at high speeds with low pressure. Let the tool do the work.

- Place a piece of wood or another solid material (a “backer board”) behind the carbon fiber. This supports the material as the drill bit exits, preventing the layers from splitting.

FAQ: Your Carbon Fiber Questions Answered

- 1. Is carbon fiber really stronger than steel?

- Yes. Pound for pound, high-quality carbon fiber is about five times stronger than standard steel. Its real advantage is its incredible strength-to-weight ratio.

- 2. Can carbon fiber sheets stop a bullet?

- Standard carbon fiber sheets are not bulletproof. While they are very strong, they are also brittle and will shatter on high-velocity impact. Bulletproof applications use specialized composites that often combine carbon fiber with other materials like Kevlar (aramid fiber) to absorb the energy of an impact.

- 3. Does carbon fiber degrade or get weak in the sun?

- The carbon fibers themselves are not affected by UV radiation. However, the epoxy resin that holds them together can be. Over time, sunlight can cause the resin to yellow and become brittle. That’s why high-quality carbon fiber parts are always finished with a UV-resistant clear coat for protection.

- 4. Why is carbon fiber so expensive?

- The high cost comes from a combination of factors. The raw precursor material (PAN) is costly, and the manufacturing process is very energy-intensive, requiring multiple stages of heating in specialized furnaces. The hands-on labor and precision required, especially for prepreg and autoclave methods, also add to the cost.

- 5. Is carbon fiber magnetic?

- No, carbon fiber is not magnetic. It’s composed almost entirely of carbon atoms, which do not have magnetic properties. This makes it useful for applications where magnetic interference must be avoided.

- 6. How long do carbon fiber parts last?

- If properly manufactured and maintained, carbon fiber can last for an incredibly long time—potentially over 50 years. It is highly resistant to corrosion and fatigue. The main threats to its longevity are UV damage (if not protected) and physical impact damage.

Conclusion: The Future is Woven

From its humble beginnings as a light bulb filament to its current status as a superstar material in the world’s most demanding industries, carbon fiber has proven its worth time and time again. Its unmatched combination of strength, stiffness, and low weight continues to push the boundaries of what is possible in engineering and design. As manufacturing techniques become more efficient and costs gradually come down, this remarkable material will only find more ways to shape our world, making our cars more efficient, our planes safer, and our equipment higher-performing.

Ready to Start Your Carbon Fiber Project?

Explore our wide selection of high-quality carbon fiber sheets, plates, and veneers to find the perfect material for your needs.