In the world of FPV drones, the debate between a CNC drone frame and a 3D printed drone frame is often framed as a simple choice between strength and customization. While a CNC-machined carbon fiber frame offers superior rigidity and performance, a 3D printed frame provides unparalleled design freedom and an incredibly low cost of failure. But the definitive answer isn’t choosing one over the other. The true secret to building the ultimate drone lies in a powerful hybrid approach. This guide provides an exhaustive deep dive into both manufacturing philosophies, comparing them across every metric—from material science and crash durability to cost and real-world performance. By the end, you will understand not just the pros and cons of each, but how to intelligently combine the precision of CNC with the resilience of 3D printing to create a drone that is truly optimized for its mission.

Table of Contents

Introduction – Two Philosophies of Creation

Every FPV drone begins its life as a collection of parts, but at the heart of every build lies a single, defining choice: the frame. This choice is more than just picking a shape; it’s a decision between two fundamentally different manufacturing philosophies. On one side, you have the precision and power of CNC machining—a method of sculpting a perfect, high-strength part from a solid block. On the other, you have the revolutionary freedom of 3D printing—the magic of building a complex object from the ground up, layer by layer.

This guide is designed to be the ultimate resource on this topic. We will move beyond a simple list of pros and cons to give you a deep, comprehensive understanding of each method. We will explore the science behind the materials, the practical realities of cost and durability, and the specific use cases where a CNC drone frame is the undisputed king, and where a 3D printed drone frame is the smarter, more innovative choice. More importantly, we will show you how the true experts don’t choose one over the other; they masterfully combine both to build the ultimate flying machines.

Prepare for a deep dive. We’ll deconstruct each frame type, put them head-to-head in a detailed comparison, and apply our findings to the real-world flying styles of racing, freestyle, and cinematic FPV. By the end, you will have a clear roadmap to making the perfect decision for your next build.

Understanding the CNC Drone Frame: The Subtractive Standard

The vast majority of high-performance drone frames on the market today are CNC machined. This method has long been the gold standard for producing parts that require a combination of high strength, low weight, and extreme precision. But what does that actually mean?

What is a CNC Drone Frame? The Art of Precision Removal

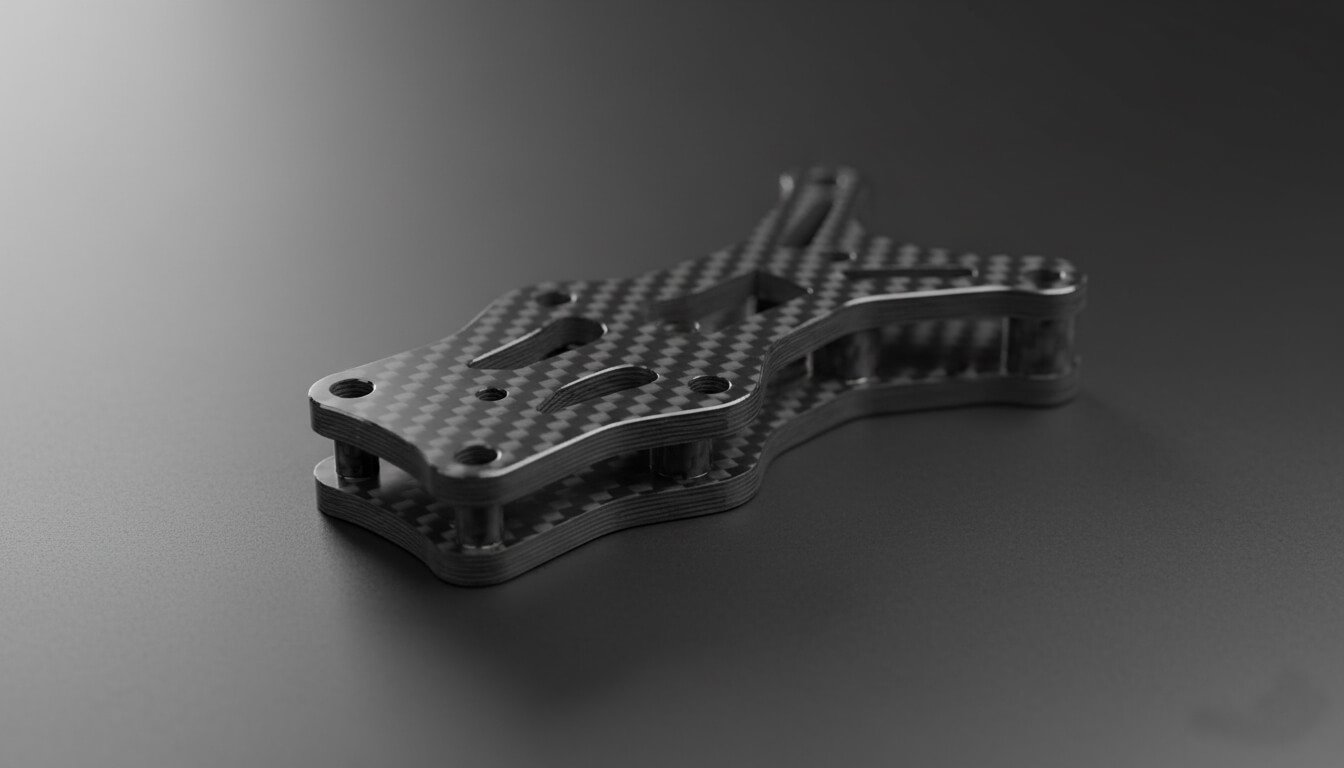

CNC stands for Computer Numerical Control, and it is a subtractive manufacturing process. The easiest way to think about it is to imagine a master sculptor starting with a solid block of marble. The sculptor carefully chips away everything that isn’t the statue, leaving a perfect form behind. A CNC machine does the same thing, but with incredible speed and robotic precision.

The process works like this: a designer creates a 3D model of a frame part in CAD (Computer-Aided Design) software. This design is then converted into a set of machine instructions called G-code. The G-code tells a CNC mill exactly where to move a high-speed cutting tool (an end mill) to carve away material from a solid block or sheet until only the final, perfectly shaped part remains.

The Materials of Choice: Strength and Rigidity

One of the biggest advantages of CNC machining is its ability to work with incredibly strong, high-performance materials. For a CNC drone frame, the options are clear:

- Carbon Fiber Plate: This is the undisputed king of FPV drone frame materials. It’s important to note that the frame isn’t cut from a 3D block of carbon. Instead, it is machined from flat sheets of carbon fiber that have been created under immense heat and pressure. This process results in a material that is exceptionally stiff, strong, and lightweight.

- Aluminum (e.g., 6061, 7075): While heavier than carbon fiber, aluminum offers excellent durability and rigidity. It is often used for the frame of larger industrial drones or for specific high-strength components on FPV drones, such as camera cages or motor mounts on some premium frames.

- Titanium: This is a premium, exotic option known for its incredible strength-to-weight ratio. Due to its high cost and difficulty to machine, titanium is typically reserved for specialized hardware like screws or custom high-stress components.

Core Characteristics of a CNC Drone Frame

Frames produced via CNC machining share a set of distinct and highly desirable traits:

- Unmatched Precision and Tight Tolerances: A CNC machine can achieve accuracies measured in thousandths of an inch. This means every screw hole lines up perfectly, and every component fits exactly as the designer intended.

- Superior Material Properties: Because the process starts with a solid, high-quality block or sheet, the final part retains the full, uncompromised strength of the original material.

- Excellent Surface Finish: CNC-machined parts are smooth and professional-looking right off the machine, requiring minimal post-processing.

- High Rigidity: The stiffness of materials like carbon fiber leads to a frame that does not flex under load. This results in a highly responsive, “locked-in” flight feel and helps to minimize vibrations.

Understanding the 3D Printed Drone Frame: The Additive Revolution

On the opposite end of the manufacturing spectrum lies 3D printing. Where CNC subtracts, 3D printing adds. This revolutionary approach has opened up a world of possibilities for drone designers and hobbyists, offering a level of freedom and accessibility that was once unimaginable.

What is a 3D Printed Drone Frame? The Magic of Layer-by-Layer Creation

3D printing, also known as additive manufacturing, is the process of building a three-dimensional object from a digital file. The analogy here is building something with LEGO bricks. You start with nothing and build your object from the ground up, one layer at a time.

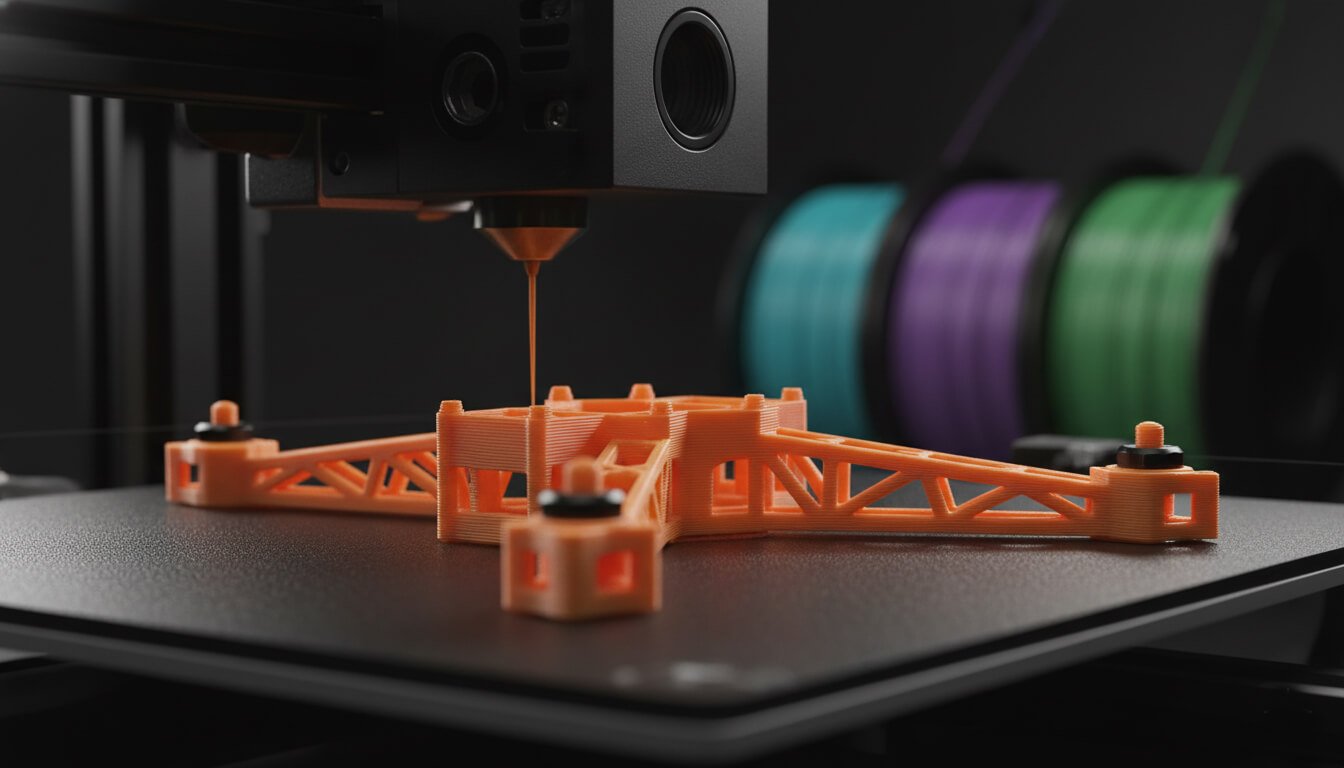

The most common type of 3D printing for drones is FDM (Fused Deposition Modeling). A 3D model (typically an STL file) is first “sliced” by software into hundreds or thousands of thin horizontal layers. The 3D printer then reads this file and deposits a thin stream of molten plastic, meticulously tracing each layer. As the plastic cools, it solidifies and fuses to the layer below it, gradually building the physical object.

The Materials of Choice: A Spectrum of Possibilities

The real magic of a 3D printed drone frame lies in the vast and ever-expanding library of materials you can use. Each plastic filament has unique properties, allowing you to choose the perfect material for a specific job:

- PLA (Polylactic Acid): This is the most common and easiest filament to print with. However, it is very brittle and has a low heat tolerance. A PLA frame will likely shatter on the first hard crash and can even warp if left in a hot car. It is fantastic for prototyping, making jigs, and non-structural parts, but not for a frame you intend to fly hard.

- PETG (Polyethylene Terephthalate Glycol): This is the workhorse for rigid 3D printed frames. It offers a great balance of stiffness (about 80% that of PLA) and far superior impact resistance. It’s the go-to choice for pilots who want to print a functional, crash-resistant 3D printed drone frame for practice or freestyle.

- TPU (Thermoplastic Polyurethane): This is the indestructible wonder material of FPV. TPU is a flexible, rubber-like filament that is virtually unbreakable. It is too flexible to be used for the main arms of a performance drone, but it is the undisputed champion for parts that need to absorb impacts, such as camera mounts, antenna mounts, bumpers, landing pads, and even entire Cinewhoop frames.

- Advanced Composites (CF-Nylon, Polycarbonate): These are engineering-grade filaments for advanced users. Nylon blended with chopped carbon fibers (CF-Nylon) can produce parts that are incredibly stiff, strong, and light, rivaling the properties of some low-grade carbon fiber. However, they are difficult to print, often requiring high-temperature printers and special handling to keep the filament dry.

Core Characteristics of a 3D Printed Drone Frame

- Unparalleled Design Freedom: This is 3D printing’s superpower. It allows for the creation of complex internal geometries, integrated mounts, and organic shapes that would be impossible or prohibitively expensive to machine.

- Rapid Prototyping and Iteration: A pilot can design a new part in the morning, print it in the afternoon, and be flight-testing it by the evening.

- Low Cost of Failure: Crashing is a part of FPV. Snapping a frame arm that cost you $0.80 in filament is a minor inconvenience, not a major expense.

- Anisotropic Properties: This is a critical concept to understand. A 3D printed part is like a stack of paper; it’s strong along the direction of the layers but much weaker when you try to pull the layers apart. This means the orientation of a part during printing is crucial to its strength.

The Head-to-Head Showdown: CNC vs. 3D Printed Drone Frames

Now that we understand the two philosophies, let’s put them in the ring for a direct, property-by-property comparison. This showdown will reveal the clear strengths and weaknesses of a CNC drone frame versus a 3D printed drone frame.

Strength, Durability, and Crash Resistance

When it comes to pure material strength, there is no contest. A high-quality CNC drone frame made from laminated carbon fiber is vastly stronger and stiffer in tension than any 3D printed plastic. It is designed to handle immense forces without flexing.

However, durability in a crash is more nuanced. A CNC carbon frame is extremely strong, but it can fail under a severe, focused impact, leading to a clean snap or delamination. A well-designed 3D printed drone frame made from PETG, while weaker overall, can sometimes absorb a surprising amount of impact energy before its brittle failure (shattering). The real star in durability, though, is TPU. 3D printed parts made from TPU are nearly indestructible, simply deforming on impact and bouncing back to shape.

Weight: A Surprising Comparison

This is a common misconception. While plastic feels lighter than carbon fiber in your hand, a 3D printed frame is almost always heavier than a CNC carbon frame of the same size and strength. To achieve the necessary durability, a 3D printed frame needs thick walls and high infill, adding significant weight. A typical 5-inch carbon fiber frame might weigh 50-70 grams, while a comparable 3D printed PETG frame will often weigh 80-120 grams. For a given strength, a CNC drone frame is always the lighter option.

Precision and Tolerances: No Contest

CNC machining is the clear winner here. A professional CNC mill can hold tolerances of ±0.025 mm. This ensures a perfect fit for every motor, screw, and electronic component. A well-calibrated hobbyist 3D printer can achieve good accuracy, typically in the ±0.1 mm to ±0.5 mm range, but it cannot match the flawless precision of a CNC machine.

Design Freedom and Customization

Here, the roles are completely reversed. A 3D printed drone frame offers virtually limitless design freedom. You can integrate camera mounts, antenna tubes, battery pads, and wire channels directly into the frame’s design. This reduces the total number of parts and allows for a level of customization that is simply impossible with the 2.5D cutting process of a CNC mill on flat sheets.

The Economics: A Deep Dive into Cost

This is where the 3D printed drone frame truly shines, especially for the hobbyist. The cost comparison can be broken down into three key areas:

- Initial Investment: A reliable FDM 3D printer capable of producing high-quality drone parts can be purchased for under $300. A hobbyist-grade CNC machine capable of cutting carbon fiber safely and accurately can easily cost $2,000 to $5,000 or more.

- Cost Per Part: The material cost for a 5-inch 3D printed PETG frame is typically between $2 and $8. A high-quality CNC-cut carbon fiber frame of the same size costs between $30 and $80.

- Cost Per Crash: This is the most crucial economic factor for an active pilot. Breaking a 3D printed arm might cost you $0.80 in filament and a couple of hours of print time. Breaking a carbon fiber arm costs $10-$25 and means waiting for a replacement part to be shipped. Over a flying season, these savings add up dramatically.

The Master Comparison Table

This table summarizes the showdown, highlighting where each method excels.

| Feature | CNC Drone Frame (Carbon Fiber) | 3D Printed Drone Frame (PETG) | Winner |

|---|---|---|---|

| Strength-to-Weight Ratio | ★★★★★ (Excellent) | ★★★☆☆ (Good) | CNC |

| Stiffness & Low Vibration | ★★★★★ (Excellent) | ★★☆☆☆ (Fair, requires tuning) | CNC |

| Precision & Tolerances | ★★★★★ (Excellent) | ★★★☆☆ (Good) | CNC |

| Design Freedom & Customization | ★★☆☆☆ (Limited to 2.5D cuts) | ★★★★★ (Excellent) | 3D Printing |

| Speed of Prototyping | ★☆☆☆☆ (Slow) | ★★★★★ (Very Fast) | 3D Printing |

| Cost per Crash | ★☆☆☆☆ (High) | ★★★★★ (Extremely Low) | 3D Printing |

Best Applications & Use Cases: Matching the Method to the Mission

The technical data is clear, but how does it translate to the real world? The best manufacturing method depends entirely on what you want to do with your drone.

For the High-Speed Racer

Verdict: CNC Drone Frame. There is no substitute. Competitive racing is a game of millimeters and milliseconds. The absolute highest stiffness and lowest weight are required for maximum responsiveness and speed. The slight flex and extra weight of a 3D printed drone frame would be a significant disadvantage on the track.

For the Aggressive Freestyler

Verdict: The Hybrid Approach. A dedicated freestyle pilot needs a frame that is both brutally strong and cheap to repair. The ideal solution is a hybrid frame that uses a thick-cut CNC carbon fiber skeleton for its core rigidity, combined with 3D printed TPU parts for all its mounts and armor. However, a full 3D printed drone frame made from PETG is an excellent and incredibly cost-effective option for practicing new tricks where you expect to crash a lot.

For the Cinematic Pilot (Cinewhoops & Proximity Flying)

Verdict: 3D Printed Drone Frame. This is a category where 3D printing is often the superior choice. The ability to print complex propeller ducts that protect both the props and the surroundings is a huge advantage. Furthermore, printing a whole frame or camera mount from flexible TPU provides incredible vibration damping, leading to silky-smooth footage. The design freedom allows for the creation of specialized rigs that are simply not possible with CNC.

Getting Started: Your Path to a Custom Frame

Feeling inspired to create your own frame? Here’s a practical guide to getting started with either method.

Your First CNC Drone Frame

- The Easy Way: Cutting Services: You don’t need to own a massive machine to get a custom CNC frame. Services like Armattan Productions are designed for the hobby. You simply upload your design file (usually a DXF file), choose your carbon fiber thickness, and they will mail you a professionally cut, high-quality frame.

- The Hard Way: Owning a CNC: For the serious hobbyist or small business, owning a CNC machine offers ultimate control. Be prepared for a high initial cost ($2,000 – $5,000+ for a capable machine), a steep learning curve for the software, and most importantly, the safety precautions required to handle hazardous carbon fiber dust.

Your First 3D Printed Drone Frame

- The Printer: The barrier to entry has never been lower. Reliable, affordable FDM printers like those from Creality, Prusa, or Bambu Lab are fantastic starting points that can produce flight-worthy parts.

- The Filament: Start with PETG for your first rigid frame to get a feel for its properties. Also, buy a spool of TPU—it will quickly become your most-used material for printing all the essential accessory parts.

- The Design: You don’t have to be a CAD expert. There are vast online repositories like Thingiverse, Printables, and MyMiniFactory that are filled with thousands of free, community-tested drone frame designs ready to download and print.

The Hybrid Approach: The Gold Standard of Modern Drone Design

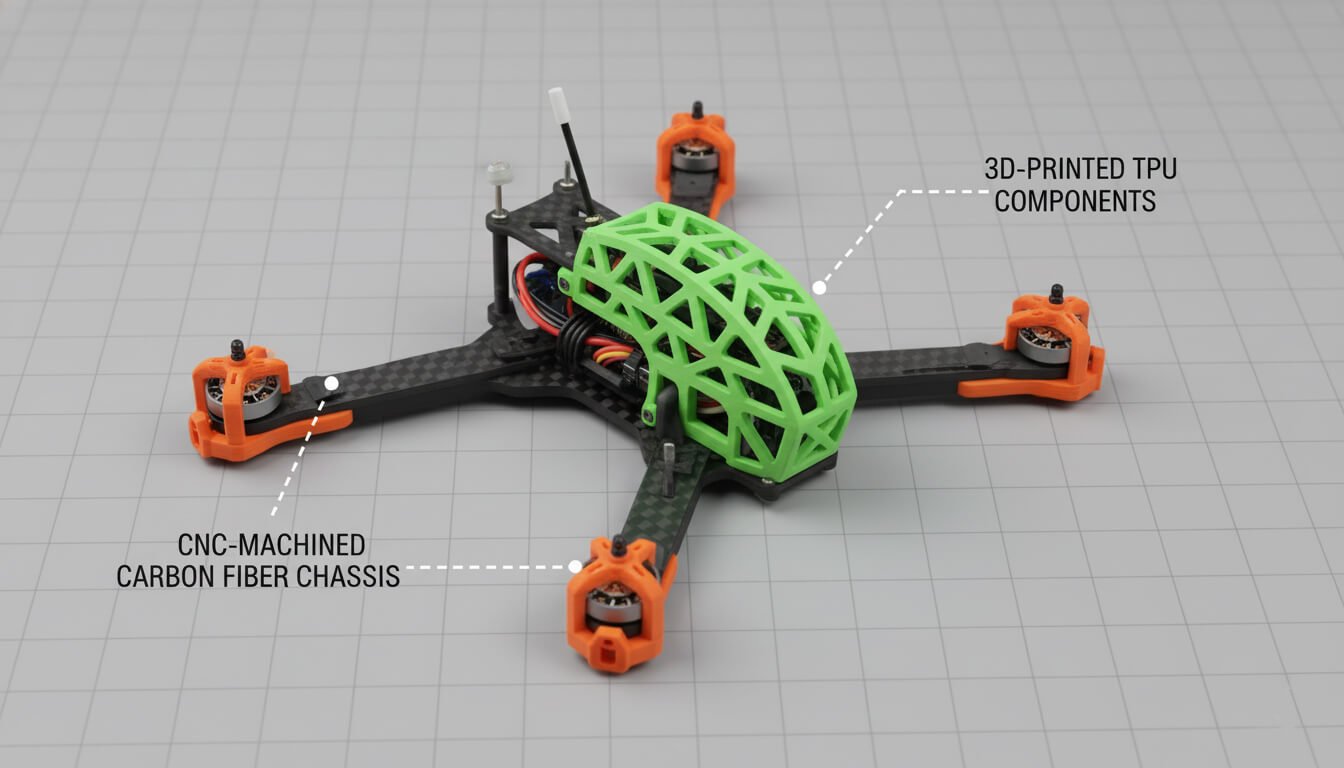

After comparing the strengths and weaknesses, a clear conclusion emerges for the pilot who wants it all: the smartest choice is not “versus,” but “and.” The modern, high-performance drone frame is a hybrid, an intelligent combination that leverages each manufacturing process for its greatest strengths.

The Guiding Principle: Rigidity vs. Flexibility

The philosophy behind the hybrid drone design is simple and effective. You separate the drone’s components into two categories based on their function:

- The Skeleton: These are the parts that form the core structure. They must be absolutely rigid to handle flight forces and provide a responsive feel.

- The Armor and Mounts: These are the parts that protect your expensive electronics and need to absorb impacts or damp vibrations.

By assigning the right manufacturing method to each category, you create a drone that is both a top-tier performer and incredibly resilient.

CNC Machined Parts: The Rigid Skeleton

These components are the non-negotiable foundation of a performance drone and are almost exclusively cut from high-grade carbon fiber plate.

- The Arms: The arms must be CNC-machined. They handle the immense thrust from the motors, and their stiffness is critical for preventing oscillations and providing a direct, “locked-in” connection between your stick inputs and the drone’s response.

- The Body Plates (Top, Bottom, Mid): These plates form the central chassis. A rigid CNC-cut core ensures that the frame maintains its structural integrity during hard crashes and provides a solid, protected housing for the electronics stack.

3D Printed Parts: The Customized Armor & Mounts

These components are where 3D printing, specifically with TPU, transforms a good frame into a great one.

- FPV & HD Camera Mounts: A flexible TPU mount is essential. It absorbs high-frequency vibrations from the frame, cleaning up your FPV feed and eliminating the “jello” effect from your HD footage. In a crash, it deforms to protect your expensive camera instead of transferring the impact force.

- Antenna Mounts: VTX and receiver antennas have fragile connectors that can easily snap off. A flexible TPU mount allows the antenna to bend out of the way during a crash, saving you from costly repairs.

- Bumpers, Arm Guards, and Landing Skids: These are sacrificial armor. Printed in TPU, their job is to absorb the scrapes and impacts at the most exposed parts of the drone, protecting the motors and the edges of the carbon fiber arms.

The Hybrid Drone Breakdown (Summary Table)

This table clearly defines the role of each process in a modern, optimized drone.

| Part | Manufacturing Method | Recommended Material | Primary Function / “Why?” |

|---|---|---|---|

| Arms & Body Plates | CNC Machining | Carbon Fiber Plate | Structural Rigidity: Provides the strong, non-flexible skeleton for flight performance. |

| Camera Mounts | 3D Printing | TPU | Vibration Damping & Impact Protection: Ensures smooth video and protects cameras. |

| Antenna Mounts | 3D Printing | TPU | Flexibility: Prevents snapping fragile antenna connectors in a crash. |

| Arm Guards / Bumpers | 3D Printing | TPU | Sacrificial Armor: Absorbs impacts and protects the core frame and motors. |

Conclusion – The Smartest Choice is a Hybrid One

The debate of “CNC vs. 3D Printed Drone Frames” ultimately leads to a clear and modern answer: the question itself is flawed. The true winner isn’t one method over the other, but the intelligent and strategic integration of both. They are not competitors; they are partners in creating the perfect flying machine.

A CNC drone frame provides the high-performance, rigid skeleton that is absolutely essential for responsive and stable flight. The components from a 3D printed drone frame provide the customizable, resilient armor that allows the drone to survive the harsh realities of FPV. The hybrid drone is the result of this powerful synergy. It represents the pinnacle of modern FPV design—a machine that is strong where it needs to be, flexible where it matters, and perfectly tailored to the pilot’s mission.

FAQ (Frequently Asked Questions)

Q1: Which is actually stronger, a CNC carbon fiber frame or a 3D printed frame?

For the same weight, a CNC carbon fiber frame is significantly stronger and stiffer. A 3D printed frame can be made to be very durable, especially for practice, but it will be much heavier than a carbon fiber frame that offers the same level of crash resistance.

Q2: Which is cheaper to crash?

A 3D printed drone frame part is overwhelmingly cheaper to crash. A replacement TPU camera mount might cost pennies in plastic and a few hours of print time, whereas a replacement carbon fiber arm can cost $10-$25 and requires waiting for shipping. This makes the hybrid approach very cost-effective for repairs.

Q3: Can I competitively race with a fully 3D printed drone frame?

It is highly unlikely. The extra weight and flexibility of even the most advanced 3D printed plastics put them at a significant performance disadvantage compared to the ultra-light, ultra-stiff CNC drone frames used by competitive racers.

Q4: What is a “hybrid drone frame”?

A hybrid frame is the modern standard for high-performance drones. It combines a CNC-machined carbon fiber skeleton (the arms and body plates) for rigidity with 3D printed TPU parts (camera mounts, antenna holders, bumpers, etc.) for impact absorption, vibration damping, and customization.

Q5: What is the best plastic for 3D printing drone parts?

For any part that needs to be flexible and indestructible, like camera and antenna mounts, TPU is the absolute best choice. For pilots wanting to experiment with a fully rigid printed frame for practice, PETG offers a good balance of strength, impact resistance, and ease of printing.

Q6: If I’m a beginner, what kind of frame should I start with?

A beginner should start with a durable, freestyle-oriented hybrid frame. The strong CNC carbon fiber core will survive many crashes, while the cheap and easy-to-replace 3D printed TPU parts will protect your expensive camera and antennas, saving you a lot of money and frustration as you learn.