When comparing carbon fiber and steel, there is no single “better” material; instead, each excels in different arenas. Carbon fiber is a lightweight champion, offering an unparalleled strength-to-weight ratio that makes it up to five times stronger than steel at a fraction of the weight, ideal for high-performance applications like aerospace and supercars where every gram matters. Steel, on the other hand, is the cost-effective titan of industry, prized for its immense durability, impact resistance, and compressive strength, making it the backbone of construction and mass-market manufacturing. This guide provides a comprehensive, data-driven showdown between these two materials, exploring their unique properties, real-world applications, and the critical trade-offs in performance, cost, and durability to help you understand which material is the right choice for any given project.

Table of Contents

Introduction – Clash of the Titans

In the world of engineering and design, a constant battle rages between tradition and innovation. Nowhere is this more apparent than in the showdown between two powerhouse materials: steel and carbon fiber. Steel is the industrial titan, the literal and figurative bedrock of our modern world. It forms the skeletons of our tallest skyscrapers, the hulls of our mightiest ships, and the frames of the cars that millions drive every day. It’s strong, reliable, and abundant.

Then there’s the challenger. Carbon fiber is the high-tech contender, born from the laboratory and honed in the world of aerospace and Formula 1 racing. It’s a material that seems to defy the laws of physics, promising a future that is lighter, stronger, and more efficient. It whispers of flying cars, feather-light prosthetics, and unimaginable speed.

But this isn’t just an academic debate. The choice between these materials has profound consequences, dictating the performance, safety, and cost of everything around us. This guide will serve as your ultimate resource, providing the most comprehensive, data-driven comparison available. We will go beyond the hype to explore the fundamental science, the real-world trade-offs, and the specific scenarios where each of these incredible materials truly shines.

What is Steel? Understanding the Bedrock of Industry

Before we can fairly compare it to the newcomer, it’s essential to understand the material that has defined construction and manufacturing for over a century. Steel is not just one thing; it’s a vast family of materials with a rich history and incredible versatility.

Defining Steel: More Than Just Iron

At its core, steel is an alloy, which means it’s a metal made by combining two or more metallic elements. The primary ingredient is iron, but the magic happens when a small amount of carbon is added. While pure iron is relatively soft, adding just a tiny percentage of carbon—typically less than 2%—dramatically increases its strength and hardness. This simple but brilliant innovation is what transformed iron into the powerhouse we know as steel.

A Family of Materials: The Main Types of Steel

Engineers can fine-tune the properties of steel by adding other elements, creating thousands of different grades for specific jobs. However, they generally fall into a few main categories:

- Carbon Steel: This is the workhorse of the steel family and the most common type. Its properties are determined mainly by the amount of carbon it contains. It’s used for everything from the structural beams in buildings to the body panels of your car.

- Alloy Steel: When you need more performance, you turn to alloy steels. By adding elements like manganese, nickel, chromium, and molybdenum, you can enhance properties like hardness, toughness, and fatigue resistance. Chromoly steel (4130) is a famous example, prized in high-performance bicycle frames and race car roll cages for its excellent strength-to-weight ratio compared to standard steel.

- Stainless Steel: What happens when you add a significant amount of chromium (typically over 10%) to steel? You get stainless steel. The chromium creates a microscopic, invisible layer on the surface that is “passive,” meaning it protects the iron underneath from rusting. This makes it essential for medical instruments, food processing equipment, and applications in corrosive marine environments.

Key Characteristics at a Glance

One of the most important properties of steel is that it is isotropic. This is a technical term that simply means its strength and stiffness are the same in all directions. You can pull, push, or bend it from any angle, and it will behave predictably. This makes it incredibly easy for engineers to design with, as its properties are consistent and well-understood.

What is Carbon Fiber? Deconstructing the Advanced Composite

Now let’s turn to the challenger. The term “carbon fiber” is often used as a catch-all, but it’s crucial to understand that it is fundamentally different from a metal like steel. It is not a pure substance but a meticulously engineered composite material.

Defining Carbon Fiber: A Team Effort

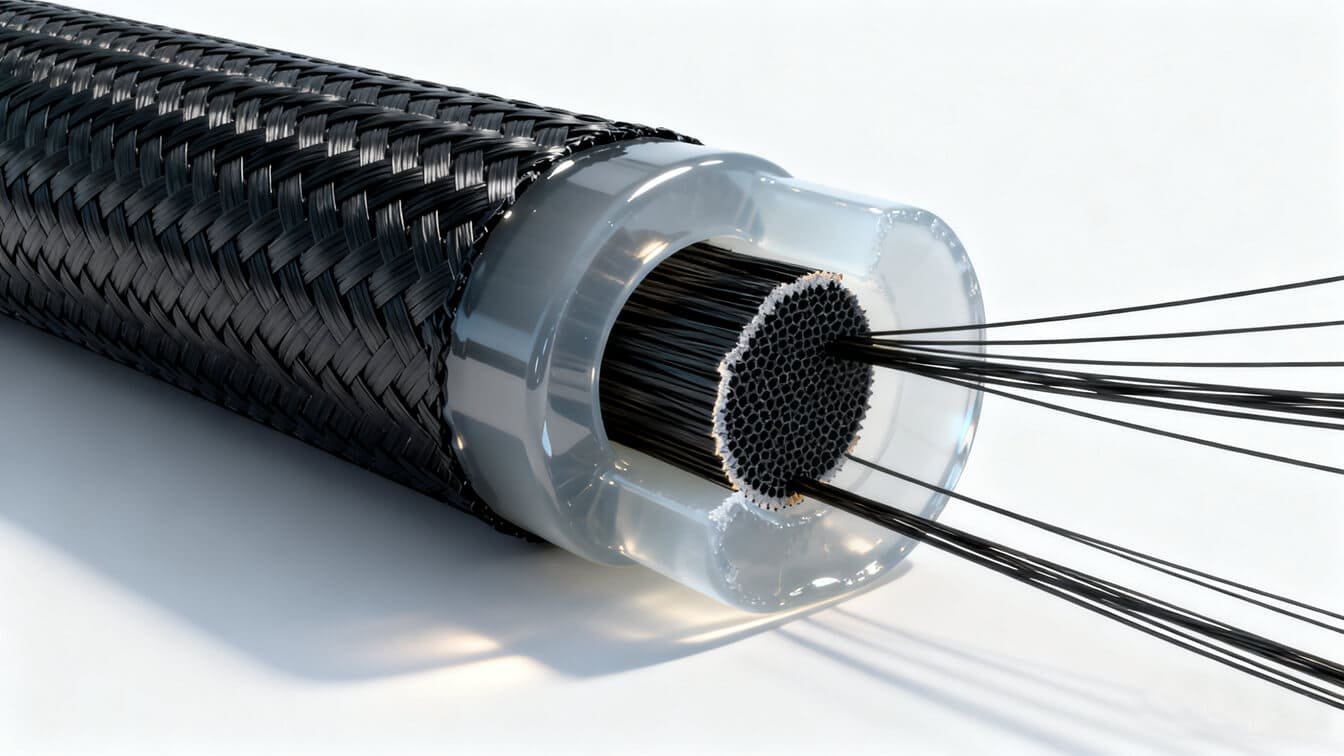

The material we call carbon fiber is more accurately known as Carbon Fiber Reinforced Polymer (CFRP). It is made from two primary components that work together as a team:

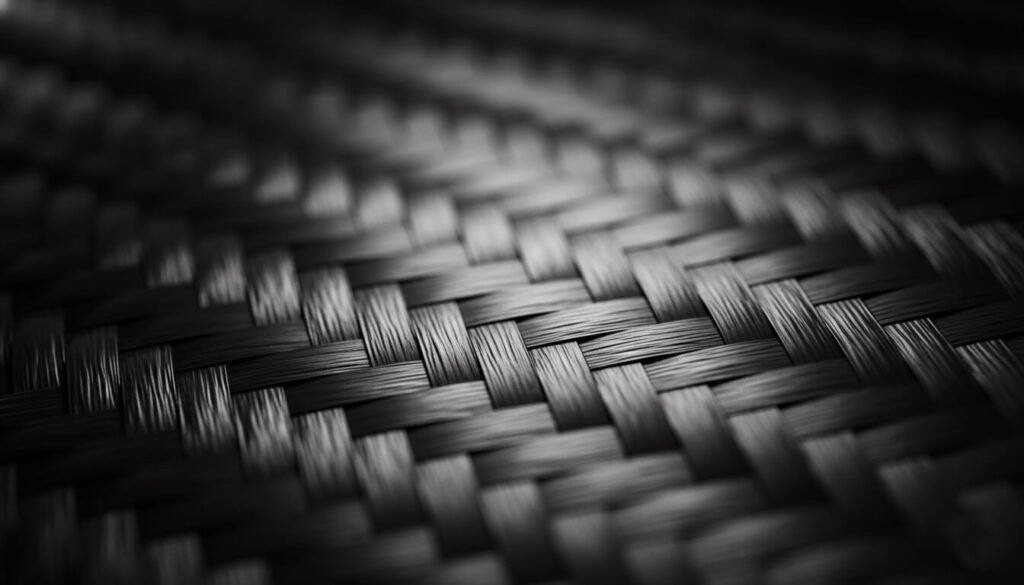

- The Reinforcement (The Carbon Fibers): These are the stars of the show. They are microscopic filaments composed almost entirely of carbon atoms, each one thinner than a human hair. These fibers are incredibly strong when pulled on (high tensile strength) and very stiff. They provide all the performance characteristics the material is famous for.

- The Matrix (The Polymer Resin): The fibers on their own are like a bundle of strong thread—not very useful for building a solid object. The matrix, typically an epoxy resin, acts as the glue that holds everything together. The carbon fibers are impregnated with this liquid resin, which then hardens (cures) to lock the fibers in place, protect them from damage, and transfer loads and stresses throughout the part.

A simple and effective analogy is to think of CFRP as high-tech reinforced concrete. The carbon fibers are like the steel rebar, providing the immense tensile strength, while the epoxy resin is like the concrete, giving the structure its shape and rigidity.

Key Characteristics at a Glance

Unlike steel, carbon fiber is anisotropic. This means its properties are directional. A sheet of carbon fiber is incredibly strong along the direction of its fibers but is much weaker if you try to pull it apart in other directions. While this sounds like a weakness, it’s actually a massive advantage for clever engineers. By carefully layering sheets of carbon fiber at different angles (a process called “layup”), they can create a part that is strong and stiff *exactly* where it needs to be, without adding any unnecessary weight. It is a material that can be precisely tailored to the job at hand.

The Ultimate Comparison: A Property-by-Property Showdown

Now that we understand what these materials are, let’s put them head-to-head in the categories that matter most to engineers, designers, and consumers.

Strength: A Nuanced Battle

The question “Is carbon fiber stronger than steel?” is the most common one, but the answer is not a simple yes or no. Strength can be measured in several ways.

- Tensile Strength (Pulling Force): In this category, carbon fiber is the undisputed champion. It is designed to resist being pulled apart, and its tensile strength can be up to 10 times higher than that of typical steel. This is its headline advantage.

- Compressive Strength (Pushing Force): Here, steel is generally superior. While carbon fiber is strong in tension, it’s less effective at handling compressive loads. Under intense compression, the thin fibers can buckle, or the resin matrix can fail.

- Failure Mode: The Critical Difference for Safety: This is perhaps the most important distinction.

- Steel (Ductile Failure): Steel is tough. When it’s overloaded, it will bend, stretch, and deform before it finally breaks. This provides a visible warning and absorbs a tremendous amount of energy, which is why it’s used for things like car bumpers and safety cages.

- Carbon Fiber (Brittle Failure): Carbon fiber does not have a “yield point.” It remains rigid and shows no sign of stress until it reaches its absolute limit, at which point it can fail suddenly and shatter. This lack of warning requires engineers to use larger safety margins in their designs.

The Deciding Metric: Strength-to-Weight Ratio

Since carbon fiber is so much lighter than steel, a true comparison requires looking at their strength-to-weight ratio (or specific strength). This tells you how strong a material is *for its weight*. In this metric, there is no contest. Carbon fiber is in a league of its own.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Specific Strength (Strength-to-Weight) |

|---|---|---|---|

| Carbon Fiber (Standard) | ~1.6 | ~3,500 | Excellent |

| Alloy Steel (4130) | ~7.85 | ~670 | Fair |

| Stainless Steel (304) | ~8.0 | ~505 | Poor |

For a given weight, carbon fiber can be many times stronger than even the best alloy steels. This is the property that allows it to revolutionize industries where weight is the primary enemy.

Weight & Density: A Landslide Victory for Carbon Fiber

This is the simplest and most dramatic comparison. Carbon fiber is exceptionally lightweight, while steel is dense and heavy. How much lighter is carbon fiber than steel? On average, steel has a density of around 7.85 g/cm³, whereas a carbon fiber composite has a density of about 1.6 g/cm³. This means carbon fiber is approximately 5 times lighter than steel. A component that weighs 50 pounds when made from steel could weigh as little as 10 pounds if redesigned using carbon fiber.

Stiffness (Modulus of Elasticity): It Depends on the Grade

The answer to “Is carbon fiber stiffer than steel?” is “it can be.” Steel has a very consistent stiffness (or modulus of elasticity) of around 200 Gigapascals (GPa). Carbon fiber, however, is an engineered material. Its stiffness can be tailored by using different types of fibers.

| Material | Modulus of Elasticity (GPa) |

|---|---|

| Carbon Fiber (Standard Modulus) | 70 – 230 |

| Carbon Fiber (High Modulus) | > 350 |

| Steel (All types) | ~200 |

As you can see, standard-grade carbon fiber can actually be less stiff than steel. However, engineers can select intermediate or high-modulus fibers that can be significantly stiffer than steel, allowing for parts with incredible rigidity.

Durability, Environment, and Cost

Beyond the primary metrics of strength and weight, several other factors are critical in the real world.

- Corrosion Resistance: Carbon fiber is a clear winner. It is a non-metallic composite and does not rust. Steel, unless it’s a costly stainless grade or protected with coatings, is highly susceptible to corrosion.

- Thermal Properties: The two materials are opposites. Steel expands and contracts significantly with temperature changes and is a good conductor of heat. Carbon fiber has almost zero thermal expansion, making it dimensionally stable, and it acts as a good insulator.

- Cost: This is steel’s greatest advantage. As a mass-produced commodity, steel is incredibly cheap. Carbon fiber, due to its complex and energy-intensive manufacturing process, is vastly more expensive. A finished carbon fiber part can cost 40 to 100 times more than an equivalent steel part.

Real-World Applications: Where and Why Each Material Wins

The theoretical properties are fascinating, but the real story is told in how these materials are used. The choice between them is a classic engineering trade-off between performance and cost.

Aerospace: A Carbon Fiber Stronghold

- Carbon Fiber’s Role: The fuselage and wings of modern aircraft like the Boeing 787 are now predominantly made of carbon fiber composites. It’s also used for satellite structures, rocket motor casings, and drones. Why? The unparalleled strength-to-weight ratio leads to dramatic fuel savings over an aircraft’s lifetime, which more than justifies the high initial cost.

- Steel’s Role: Steel hasn’t disappeared from aircraft. It is still essential for high-strength, high-impact components like landing gear, as well as for parts within the jet engines that must withstand extreme temperatures.

Automotive: Performance vs. Practicality

- Carbon Fiber’s Role: In the automotive world, carbon fiber is the language of speed. It is used to build the super-strong and lightweight “safety cell” or monocoque chassis of Formula 1 cars and hypercars. It’s also used for body panels, spoilers, and even wheels to reduce weight and improve handling. Why? For ultimate performance, cost is a secondary concern.

- Steel’s Role: Steel remains the king of mass-market automobiles. It is used for the frames and bodies of the vast majority of cars on the road. Why? It’s cheap, easy to manufacture in high volumes (stamping and welding), and its ductile nature provides excellent, predictable crash safety.

Construction & Infrastructure: The Reign of Steel

- Steel’s Role: The skeletons of our cities are made of steel. It is used for structural beams in skyscrapers, rebar to reinforce concrete, and the massive cables of suspension bridges. Why? Its immense compressive strength, low cost, and proven reliability are unmatched for large-scale structures.

- Carbon Fiber’s Emerging Role: While you won’t see a building made entirely of carbon fiber, it is finding a crucial niche. Carbon fiber wraps and strips are used to retrofit and strengthen existing concrete columns and bridges, especially in earthquake-prone areas. Why? Its high tensile strength and corrosion resistance make it an incredibly effective and durable repair solution.

Manufacturing, Repair, and Environmental Impact

How They’re Made: Labor-Intensive vs. Mass Production

The differences in cost are deeply tied to the way these materials are processed. Steel manufacturing is a highly automated, large-scale industrial process involving melting, casting, and rolling—techniques perfected over more than a century. Parts can be stamped out in seconds.

Creating a carbon fiber part is more like a craft. It often involves a labor-intensive process of carefully laying fabric sheets into a mold, sealing it in a vacuum bag, and curing it in a large oven (autoclave) for several hours. While automation is increasing, it remains a much slower and more complex process.

The Environmental Footprint: Production vs. Lifecycle

The environmental debate is complex. The production of carbon fiber is extremely energy-intensive, requiring about 14 times more energy than producing steel, and it generates significant greenhouse gases.

However, the story changes when you look at the entire lifecycle. In a car or an airplane, the dramatic weight savings from using carbon fiber lead to a massive reduction in fuel consumption over the product’s life. This long-term efficiency can often offset the high initial energy investment. Steel, on the other hand, is one of the most recycled materials on the planet, contributing to a circular economy. Carbon fiber recycling is possible but is currently a complex and expensive process called pyrolysis, where the resin is burned off to recover the fibers.

Decision Framework: Which Material is Right for You?

So, after all this, how do you choose? The decision always comes down to balancing priorities: performance, cost, and safety.

The Ultimate Decision Matrix

Here’s a simplified scoring system to help visualize the trade-offs:

| Criterion | Carbon Fiber | Steel |

|---|---|---|

| Strength-to-Weight Ratio | ★★★★★ (Excellent) | ★★☆☆☆ (Fair) |

| Impact Toughness | ★★☆☆☆ (Low/Brittle) | ★★★★★ (Excellent) |

| Stiffness | ★★★★★ (Tunable/Excellent) | ★★★★☆ (Very Good) |

| Corrosion Resistance | ★★★★★ (Excellent) | ★★☆☆☆ (Poor, unless stainless) |

| Initial Cost | ★☆☆☆☆ (Very High) | ★★★★★ (Low) |

| Manufacturing Ease | ★★☆☆☆ (Difficult) | ★★★★☆ (Easy) |

Choose Carbon Fiber if…

- Weight reduction is your absolute top priority.

- The application demands the highest possible tensile strength and stiffness for its weight.

- The budget can accommodate a premium, high-performance material.

- Corrosion is a major concern.

Choose Steel if…

- Cost is a primary driver, especially for high-volume production.

- You need extreme toughness, impact resistance, and predictable failure (bending, not shattering).

- The application is dominated by compressive loads.

- Ease of manufacturing, welding, and repair is important.

Conclusion – Two Champions, Different Arenas

The great debate between carbon fiber and steel reveals a simple truth: there is no single winner. Instead, we have two champions, each dominating in a different arena. They are not so much competitors as they are complementary solutions to different engineering problems.

Steel is the affordable, tough, and reliable workhorse that built our world. Its strength and versatility ensure it will remain the backbone of industry and construction for generations to come. Carbon fiber is the lightweight, high-performance specialist. It is the material of speed, efficiency, and cutting-edge design, pushing the boundaries of what we thought was possible. As technology advances, these two materials will continue to coexist, defining the look, feel, and performance of our world in their own unique ways.

FAQ (Frequently Asked Questions)

Q1: In a direct strength test, which is stronger, carbon fiber or steel?

In a pulling (tensile) test, a piece of carbon fiber is significantly stronger than a piece of steel of the same weight. However, in a crushing (compressive) or impact test, steel is much stronger and more durable because it can bend and absorb energy, whereas carbon fiber is more brittle.

Q2: Is carbon fiber bulletproof?

No, standard carbon fiber is not designed to be bulletproof. It is strong but rigid and tends to shatter on high-velocity impact. Materials specifically designed for ballistic protection, like Kevlar® (an aramid fiber), are more flexible and are engineered to absorb and dissipate a bullet’s energy.

Q3: How much does a carbon fiber bike frame cost compared to a steel one?

A carbon fiber bike frame is significantly more expensive. A good-quality steel frame might cost between $300 and $500, while a comparable carbon fiber frame can easily cost between $800 and $2,000 or even more, due to the higher material costs and the labor-intensive manufacturing process.

Q4: Will carbon fiber ever be as cheap as steel?

It is highly unlikely. The fundamental manufacturing processes for carbon fiber are far more complex, slow, and energy-intensive than those for steel. While the cost of carbon fiber is gradually decreasing as technology improves, it is expected to remain a premium material for the foreseeable future.

Q5: What happens to carbon fiber over time? Does it degrade?

The carbon fibers themselves are extremely stable and will not degrade or corrode. However, the epoxy resin that holds the fibers together can be sensitive to long-term exposure to UV radiation from the sun. This is why most carbon fiber parts are finished with a UV-protective clear coat. With this protection, a carbon fiber part can last for decades without losing its integrity.